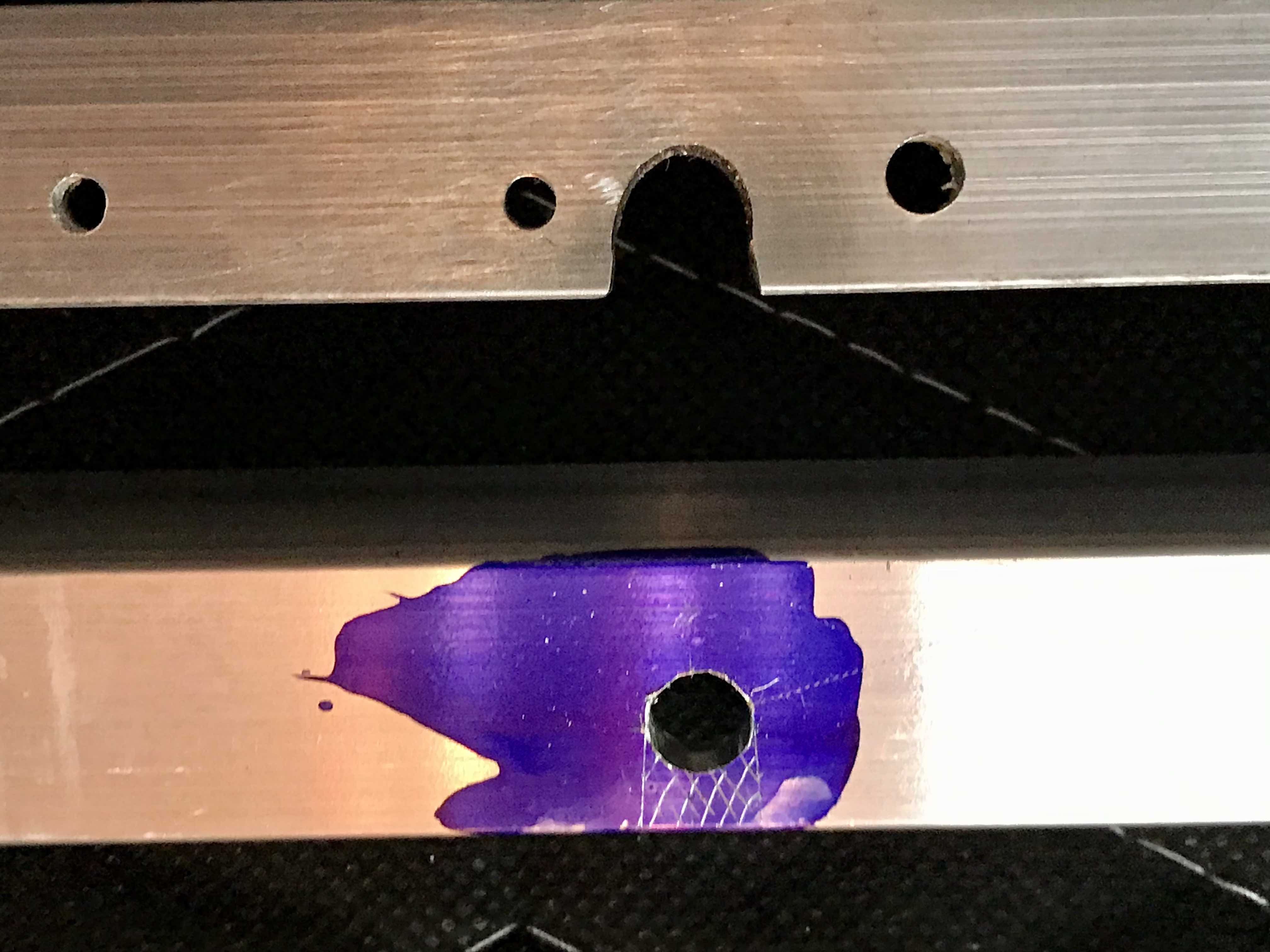

So, an unfortunate consequence of the original part that I remade a couple of days ago (Up Elevator Stop) is that it caused a hole to be drilled into the left longeron with insufficient edge distance. That part and the centering of it on the aft deck has to be extremely, extremely precise. Unfortunately, it’s hard to catch this error, as the longeron is not visible when this part is match drilled, it was only noticed upon disassembly of the tailcone.

Anyway, I decided to replace the longeron. It’s actually a fairly inexpensive piece of angle aluminum ($15-$30 depending on supplier). Possibly overkill in this case (I mean, this longeron has a huge notch that needs to be cut into it!) but it was bugging me.

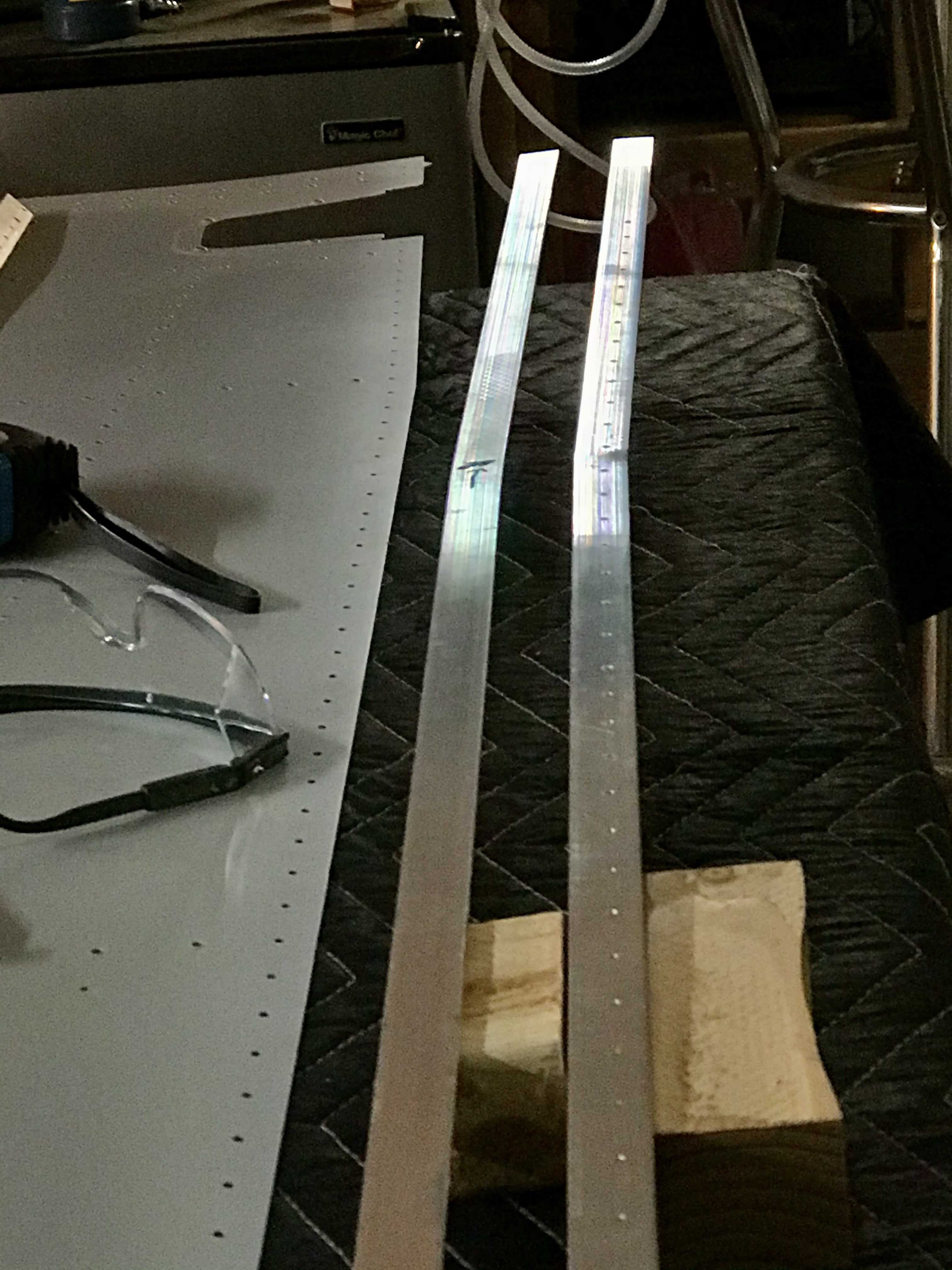

The problem is that it is long. This one has to be 98 1/8″. That’s 2 1/8″ longer than 8′, which is a huge bummer. Why? Because of shipping charges. When it goes beyond 8′, it must be shipped freight!! That increase shipping costs from say $30 to anywhere between $160-$260! 10x the cost of the material! I hadn’t actually checked with Van’s (they probably have better shipping arrangements), since their shipping department was down for a couple of weeks due to a quarantine.

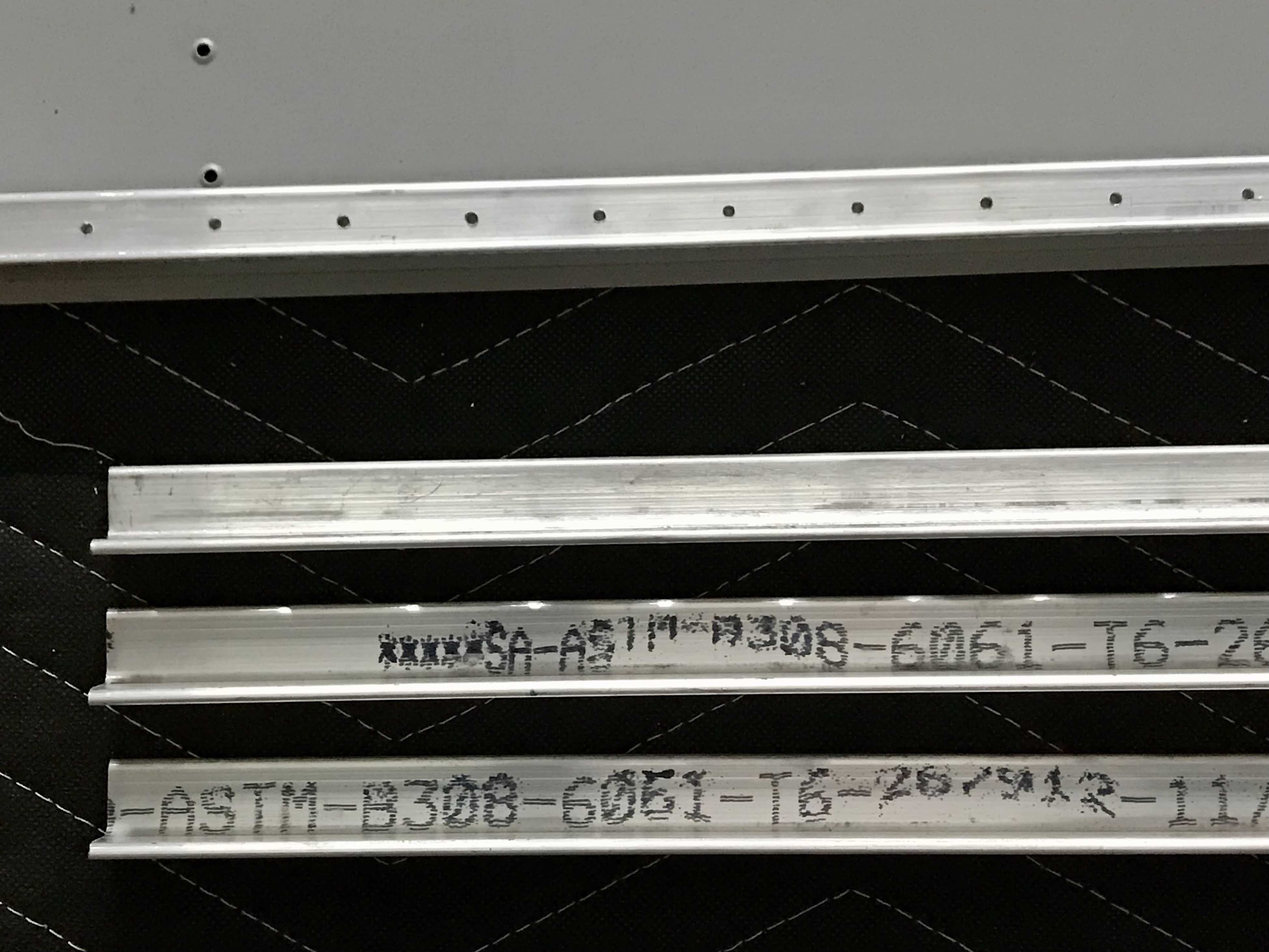

So, I found a local source! Had to be careful, since it’s not just any angle aluminum, but 6061-T6 structural aluminum. It’s much easier to find 6063-T52, and I had even found some that had the same radiused corner, but not the same treatment.

Anyway, the supplier I found was great. I was even provided with the certification of the material. But most importantly, it didn’t require a freight carrier to ship it, as I was able to slide them into my small car (just angled into the passenger footwell), with room to spare! I knew from previous experience that I can haul 9’6″ long skinny things in this car.

Picked them up today (bought 2 actually), took then to the hangar, and re-made the left tailcone longeron. It required a slight almost 2 degree bend, that I was able to do with only a little trial and error, plus a notch to be drilled & cut out.

So now I’m ready to reinstall the new longeron and just match drill it!

You did the right thing Chris. Years ago, I managed the tool and dye shop, and we used a lot of 6061 T6 Al. They are not the same material, 6061 T6 and 6053 T52, but they look alike. Keep up the exact work Chris. Chuch

LikeLiked by 1 person

Thanks Chuck, I appreciate the remark! I may end up remaking a lot of parts throughout the course of this journey, hopefully I can keep it to the easily replaceable ones 😉

LikeLike