More parts prep on the tailcone.

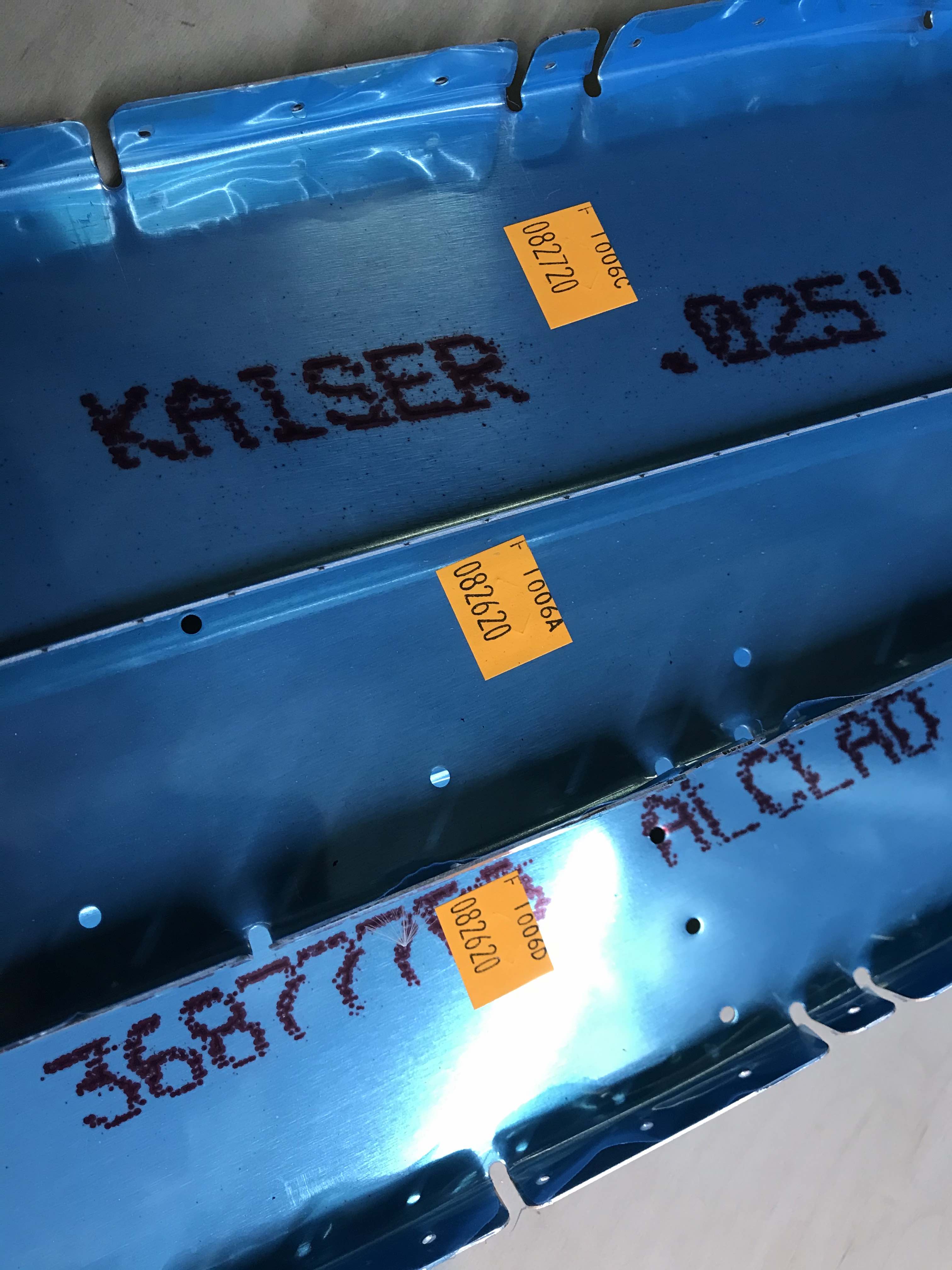

Started with deburring the four large pieces of the F-1006 bulkhead. This took a bit of time due to all the cuts in the flanges, but I got a pretty good result. Holes between 3 of the 4 pieces also had to be final size drilled. The pictures show that I have some non-final-size hole parts marked with orange labels, and others with the highlighter mark. An observation is that my non-final-size parts tend to actually have the #40 holes final sized (a #40 bit shaft can be inserted), but the #30 holes are undersized.

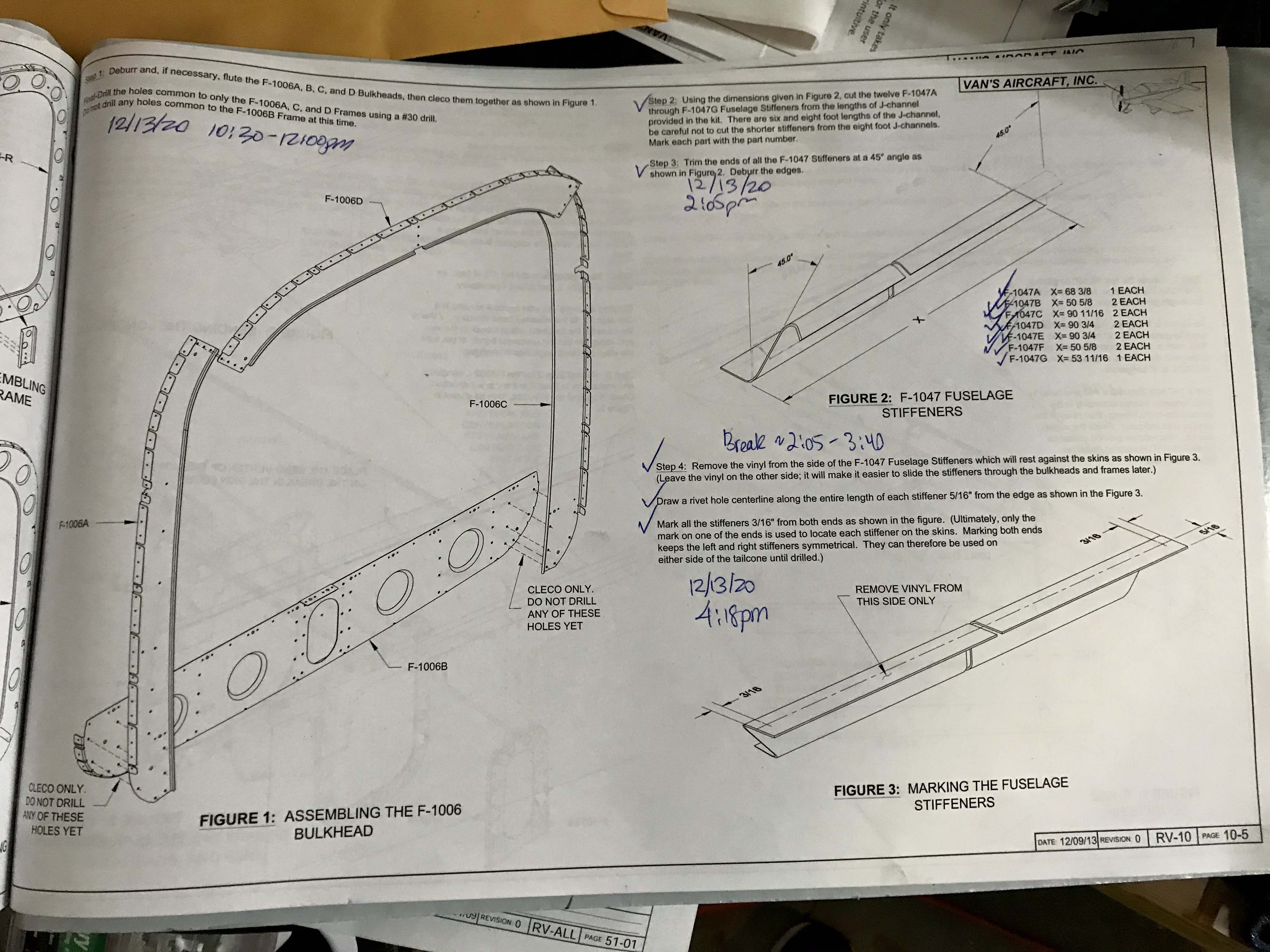

Then it was cutting, cutting, and more cutting. Twelve J-stiffeners had to be cut to varying lengths (and then at a 45 degree angle on each end). Now, 4 of them (to be given 2 different part numbers) had to be cut from 96″ to 90 3/4″… and 2 of them from 96″ to 90 11/16″ … yes, with an approximate 8 foot length, two of them have to be 1/16″ shorter! Well, OK, done. Times like this I really wished these kits used the metric system… would much rather cut pieces down to 2303.5mm or 2505mm than try and figure out and confirm and reconfirm how much different 11/16″ is from 3/4″. I’m sure I measured each piece much more than twice! At least I found a handy ruler and tape measure that I don’t have to count ticks as often.

Also, two long pieces of angle aluminum had to be cut down from 98 1/2″ all the way down to 98 1/8″. They also needed to be drilled with a 1/4″ bit then notched out, to make room for the horizontal stabilizer attachment bars. Made a lot of shavings. These pieces will become longerons in the tailcone. I kept and polished one of the small waste pieces as a keepsake.

The next step is to whang the longerons with a hammer. Figured I should start that on a fresh new day. I still have a vise-in-a-box that I need to covert to a vise-on-a-bench.