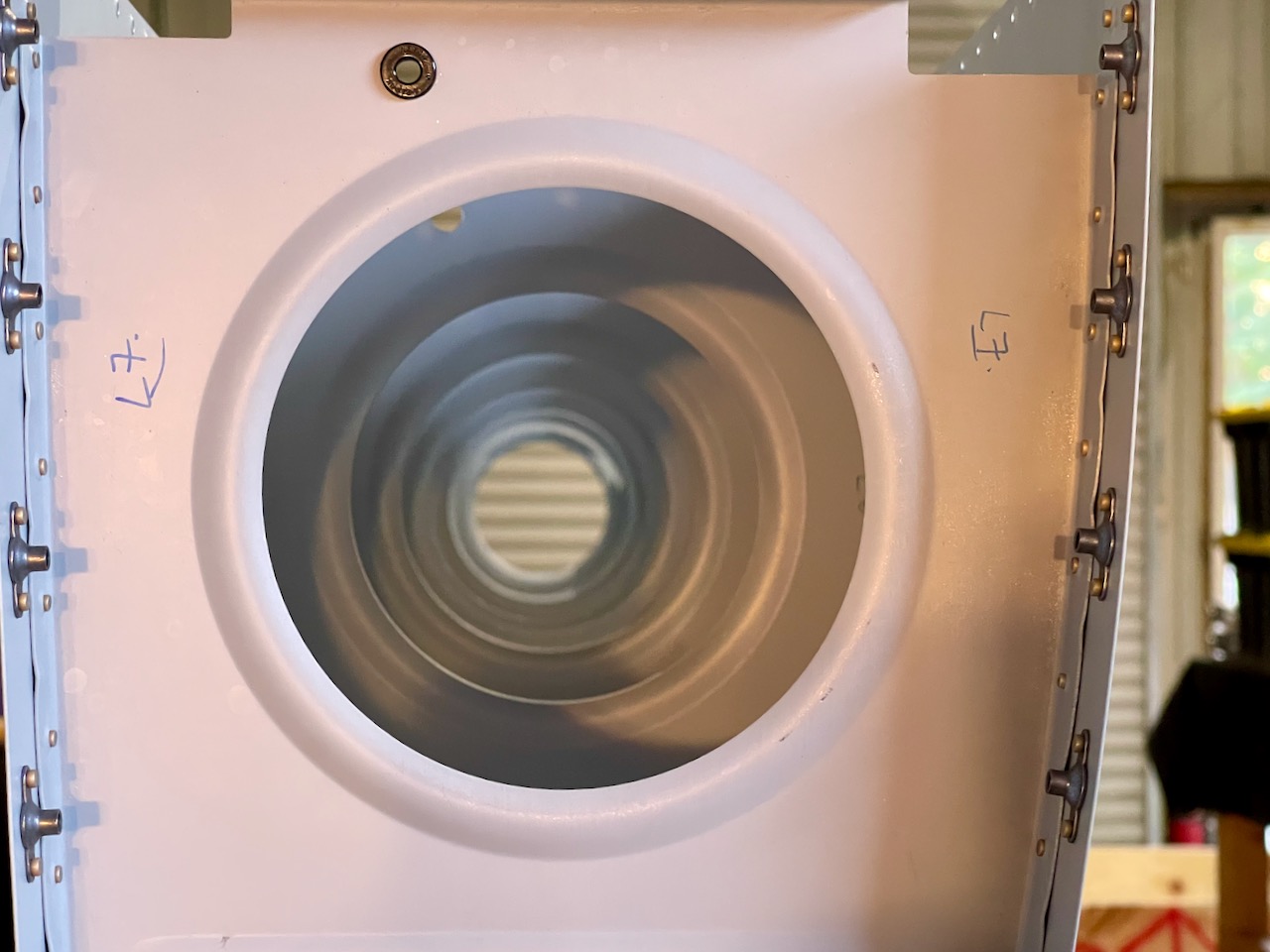

And that just refers to the metal work of course. Still need to install the stall detector to call the part itself complete. So, this is the outboard portion of the leading edge because the inboard portion is actually the fuel tank. I will probably work on the right wing counterpart of the leading edge done before I move onto the tanks.

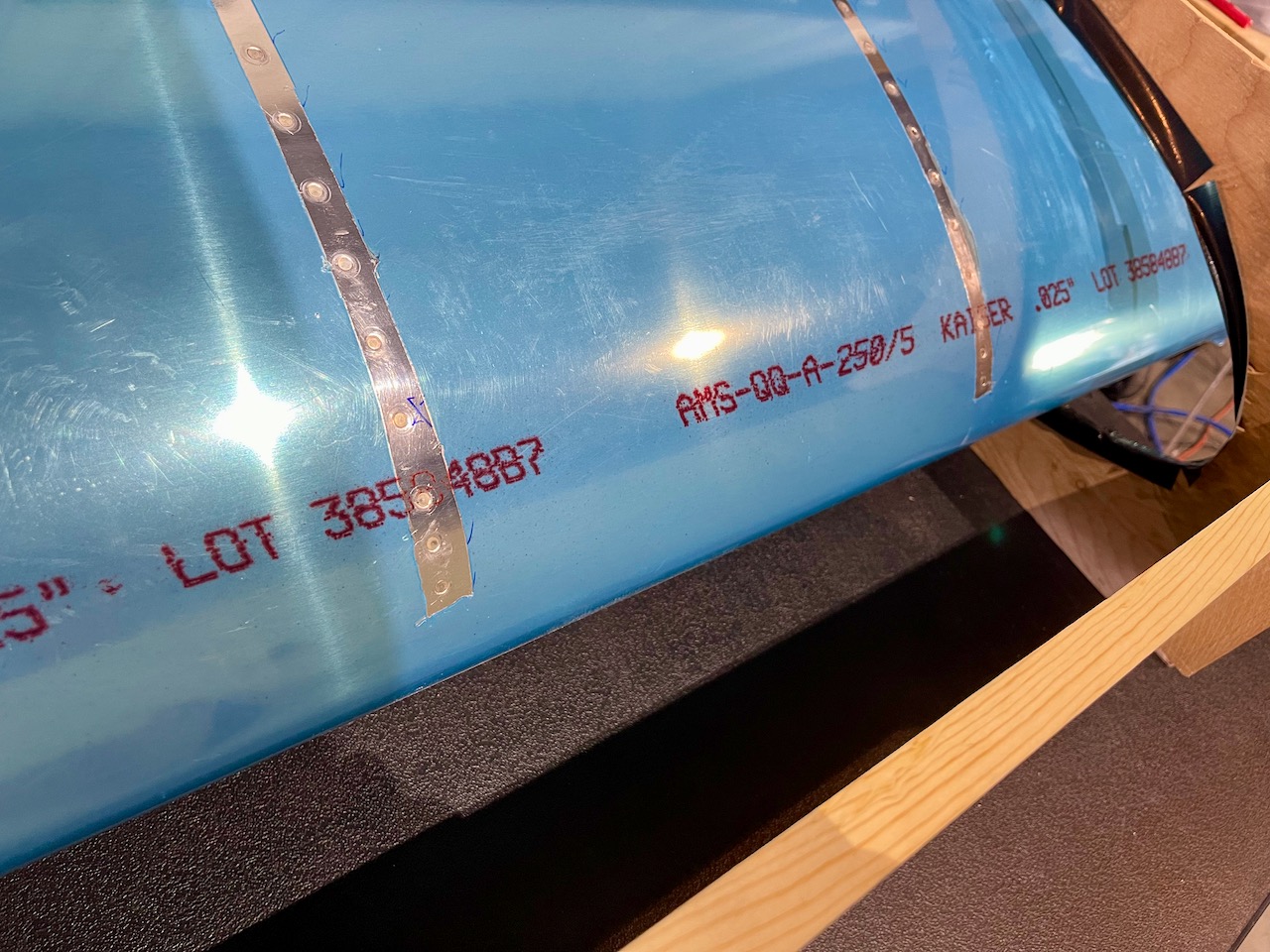

A few rivets didn’t set well and had to be drilled out. The angle gets awkward towards the nose. In fact, I don’t use the cradle for those at the very front. Overall, had to drill out a few out and reset them. So all the manufactured heads are looking good and flush. Will do an inspection of the shop heads (on the inside) next time in the hangar just to see if any are bad enough to replace. Drilling out and replacing is pretty easy with this 0.025″ thick skin.