Work primarily done on Sunday 4/24, but a couple of hours include the clecoing work which was done on Saturday 4/23, after doing some miscellaneous work around the hangar.

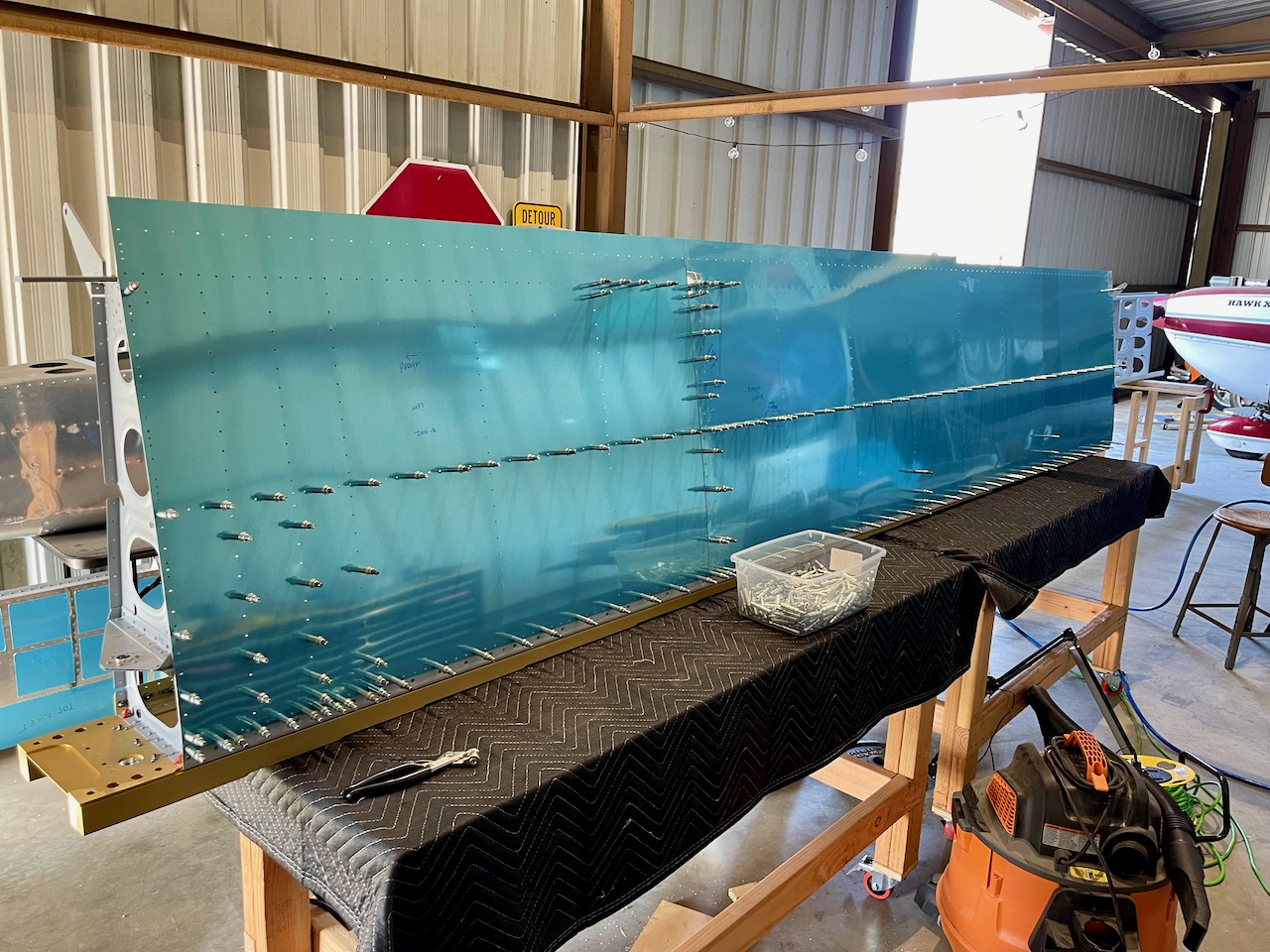

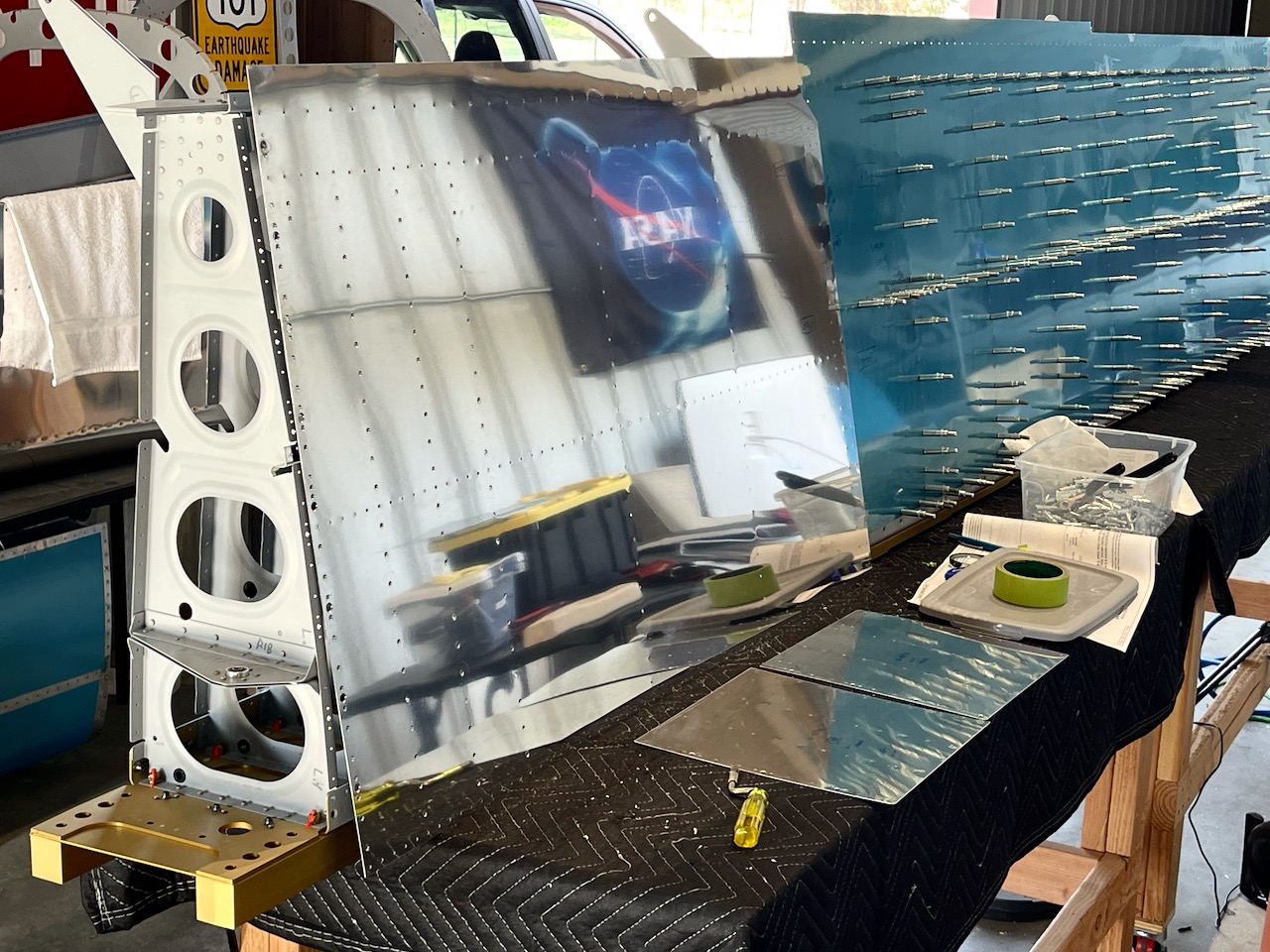

Started to prep the top skins on the left wing. This involved clecoing the two large skins (one really large) along with two wingwalk doublers and J-stiffeners to the ribs and spars.

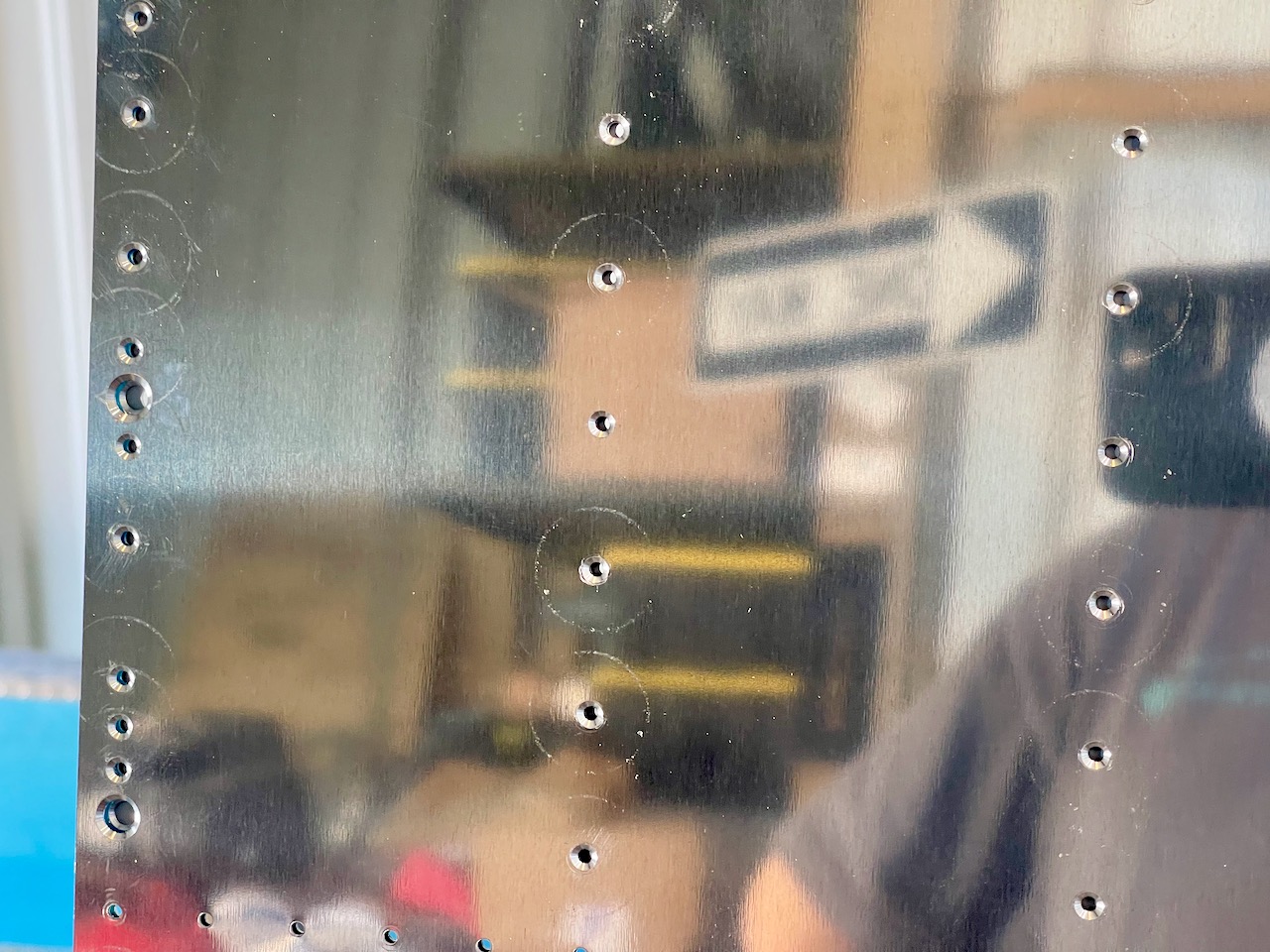

Then a few screw holes have to be drilled to a #19 size for a #8 dimple.

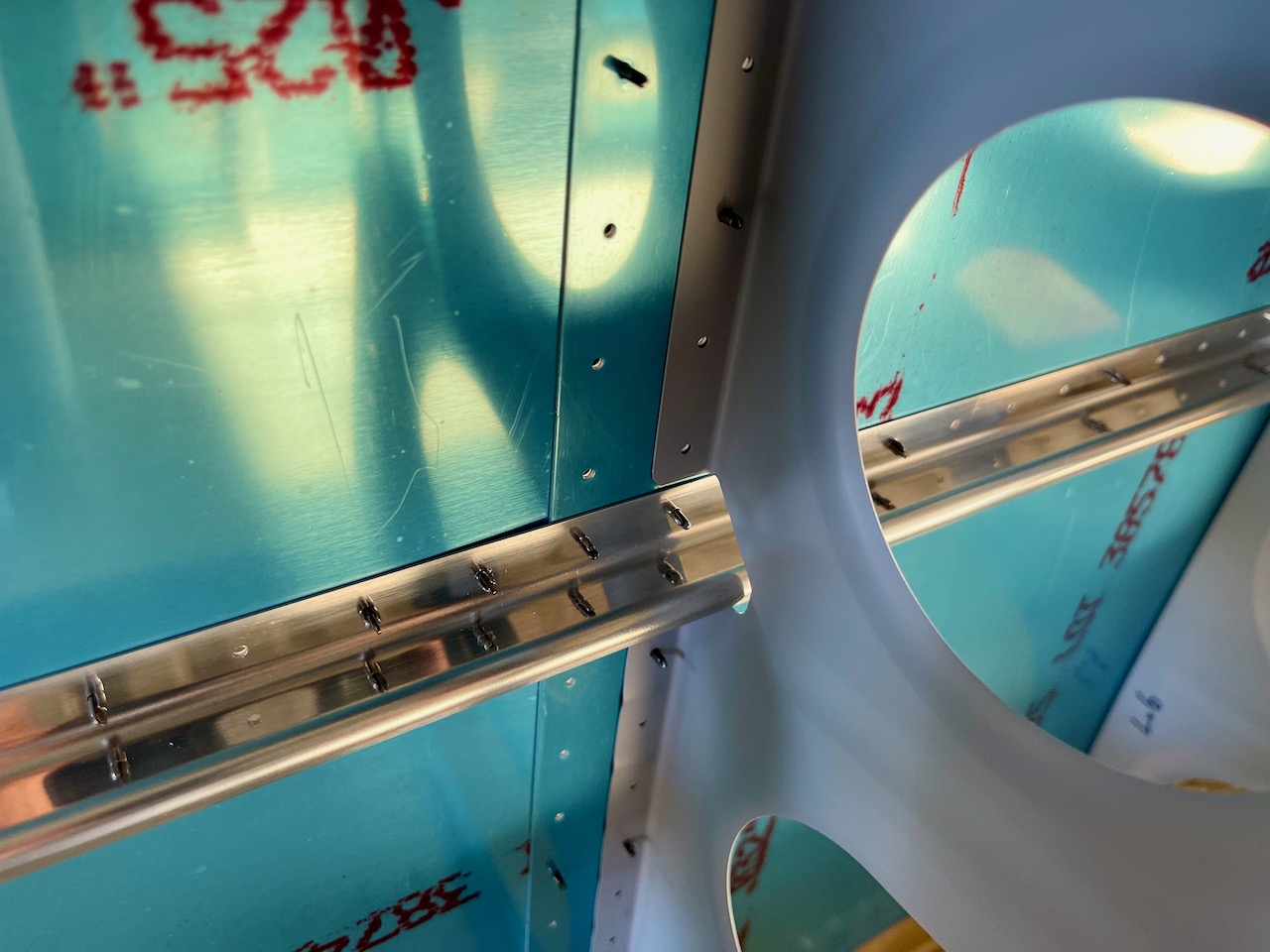

Then the plans call for final size drilling the hundreds of #40 holes. Fortunately my wing kit has mostly final sized holes from the factory. I still wanted to cleo everything together to check fit. Indeed the holes lined up perfectly, and I was able to slip in a 3/32″ rivet through most of the holes. The only few exceptions were where there were several layers of material, like the inboard most rib + doublers + topskin as well as the two columns of rivets on the lap joint between the two large skins. Visually, they looked like they lined up perfectly, but the rivet either couldn’t quite slip through or would have required some force.

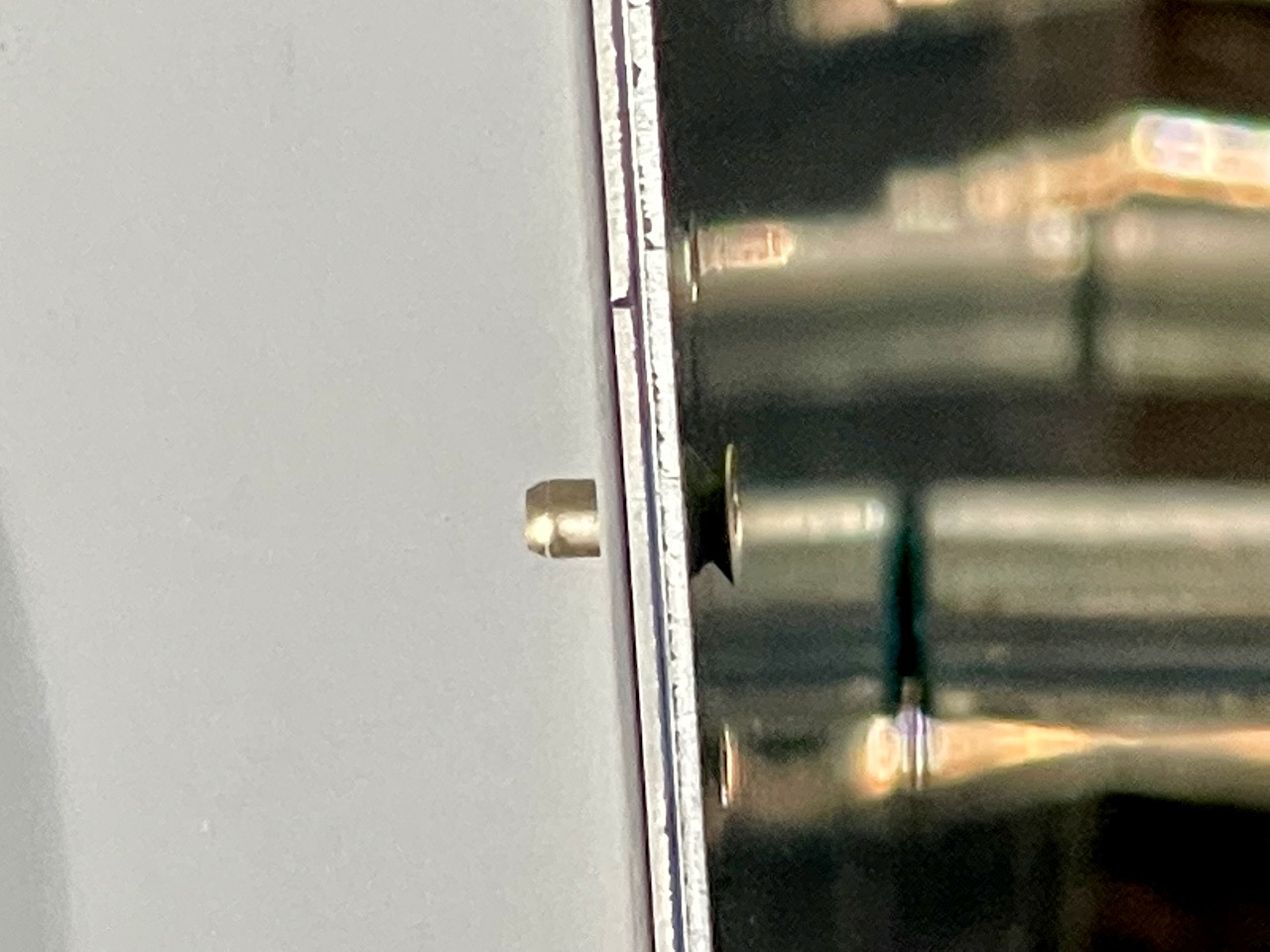

Then a bunch of countersinking, about ~100 holes. In the area where the wingwalk doublers meet the ribs and top skins, the material becomes quite thick and plans call for countersinking rather than dimpling. Indeed the combined thickness here is probably close to 0.080″ and generally material >= 0.040″ calls for countersinking, even if the materials are stacked.

The countersinks for the #8 screw dimples (dimpled skin to fit there) go quite deep, well through the top skin and mostly through the doubler.

Remainder of time was spent deburring. The doublers were fully deburred, as well as the holes on the smaller top skins. Edge deburring will wait for another day, not a task I wanted to start as it was starting to get late, and edge deburring large skins is even less fun than hole deburring.