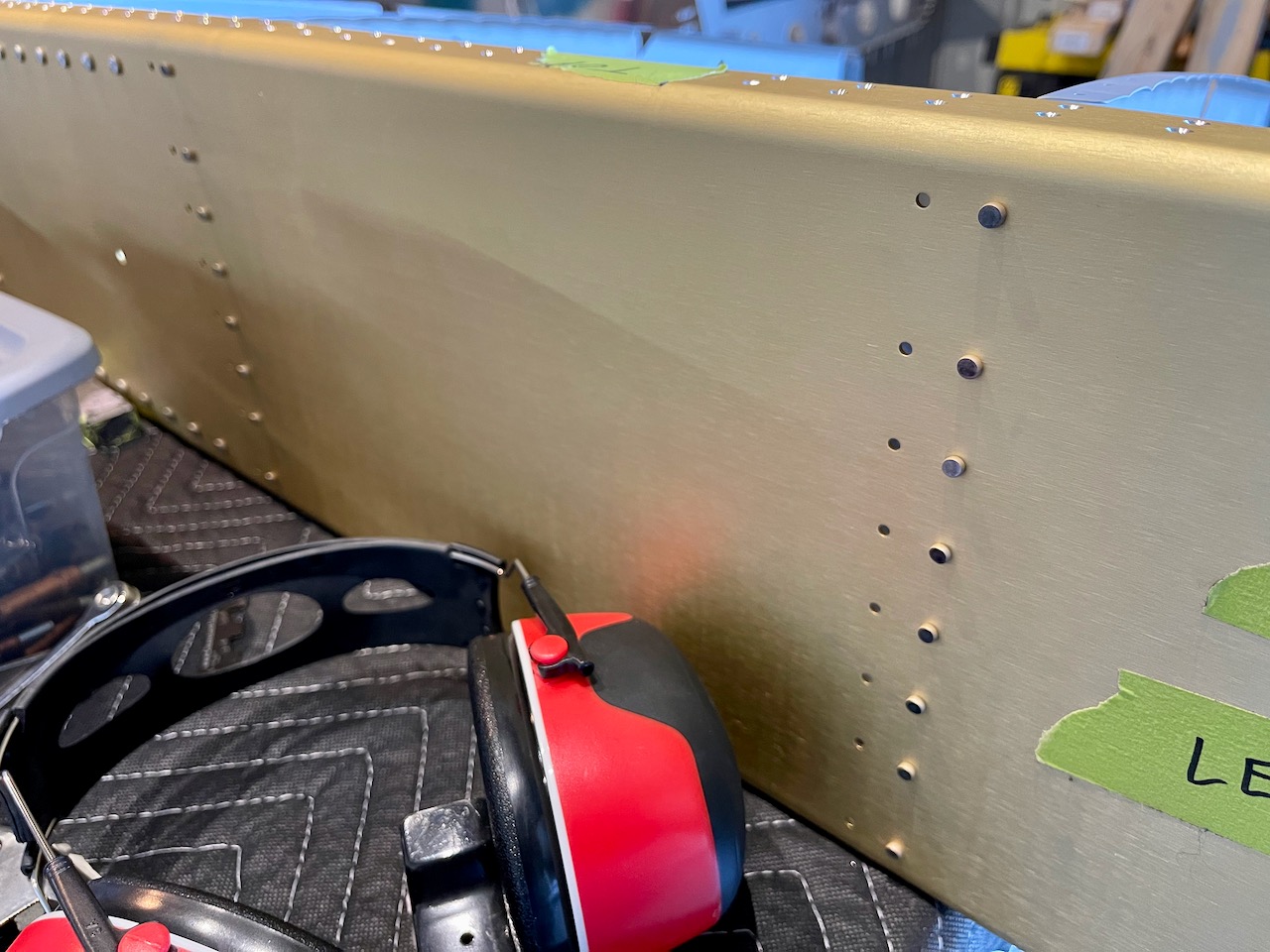

Riveted the left main ribs onto the left wing spar. This went quite well, but a few had to be drilled out and re-set (mostly due to bucking bar slippage). Same issue I had with the right wing. Switched to the large bucking bar, the small tungsten one is too dainty, in general, to hold with the higher pressure for driving the #4 rivets.

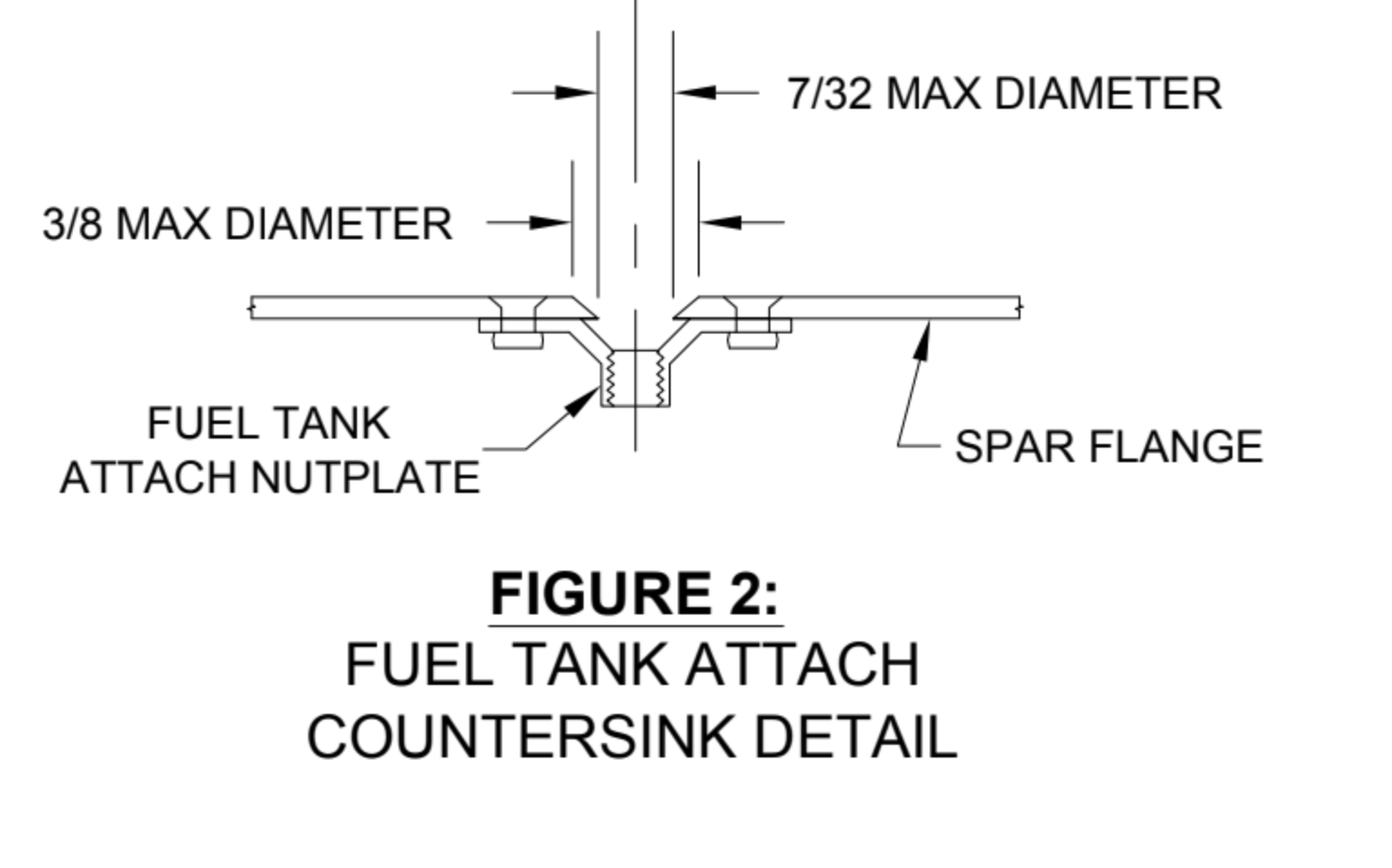

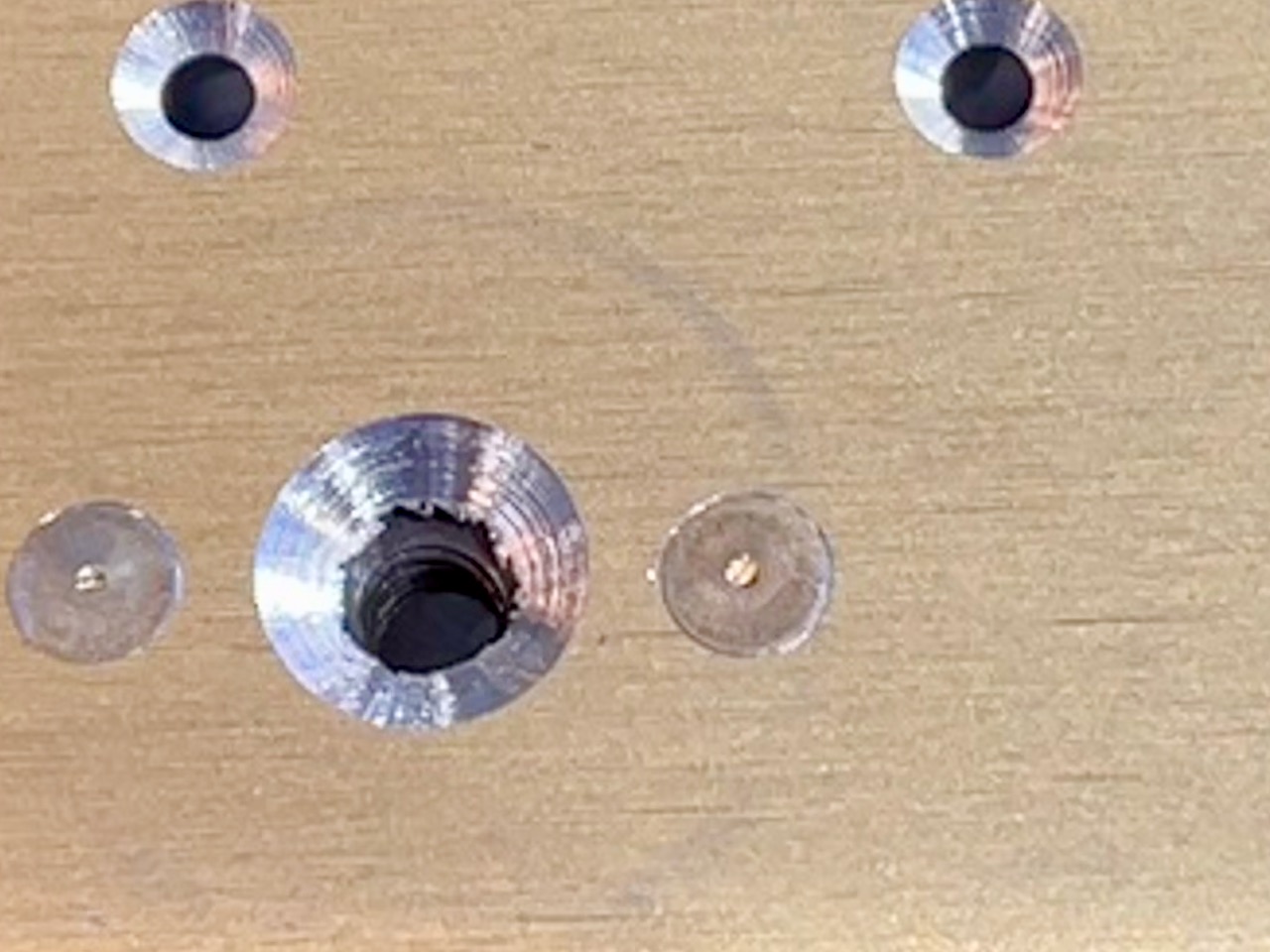

I also had to clean up the spar countersink holes for the tanks. I had done this previously on the topside of the right wing, but realized still had to do it to the left spar as well. The issue is that the countersink goes through the whole thickness of the spar, and the hole gets enlarged. The countersink cutter makes a terrible reamer in this situation, and the holes end up having rough edges. Fortunately, per the plans, the diameter of the holes can be as large as 7/32″ so a quick cleanup with a #3 drill bit (which is slightly smaller) cleans up the edges nicely.

Spars are almost done. Just have to prime the countersunk holes (I should have done that in the last chapter actually), and install a bunch of bolts.