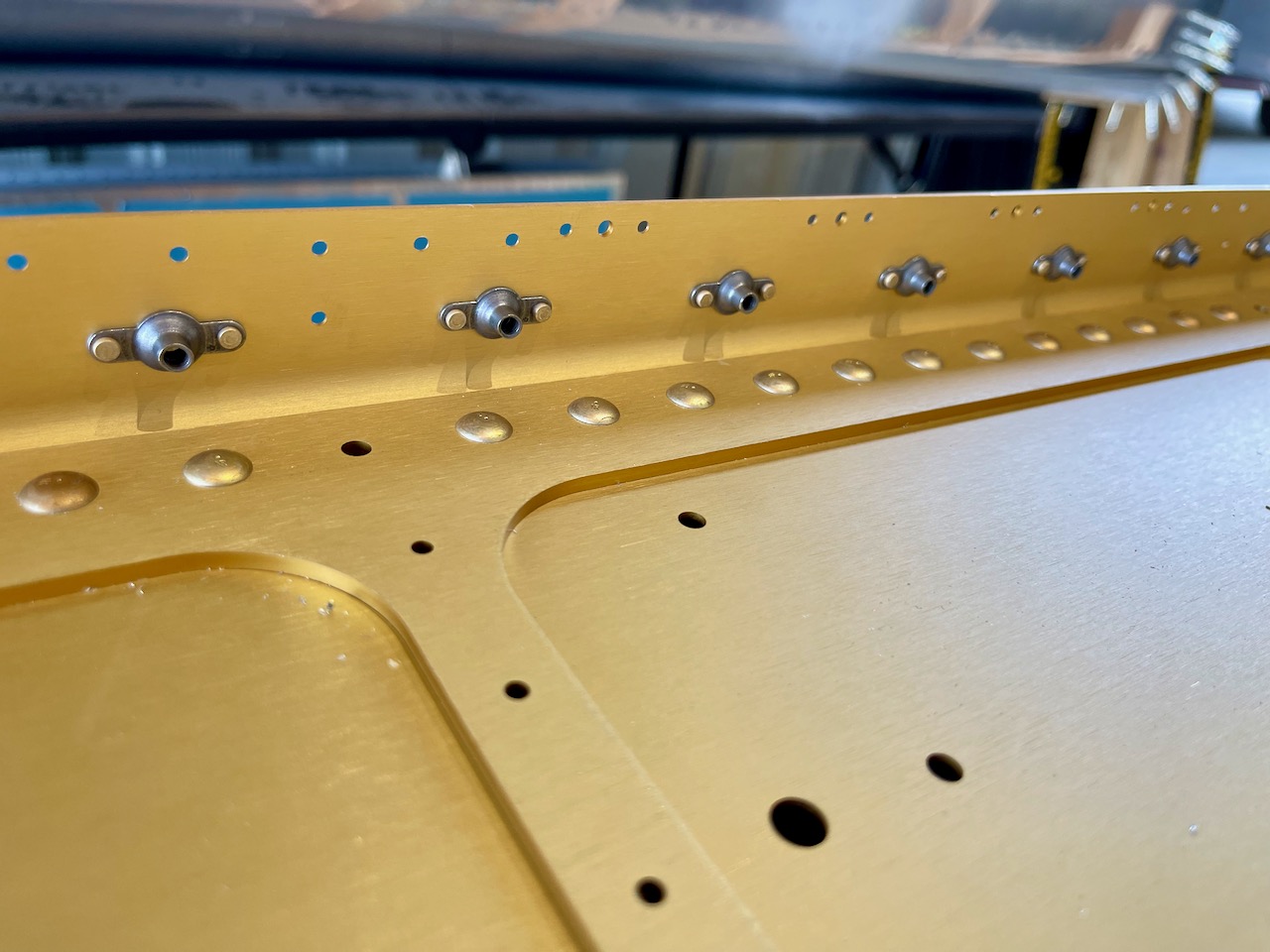

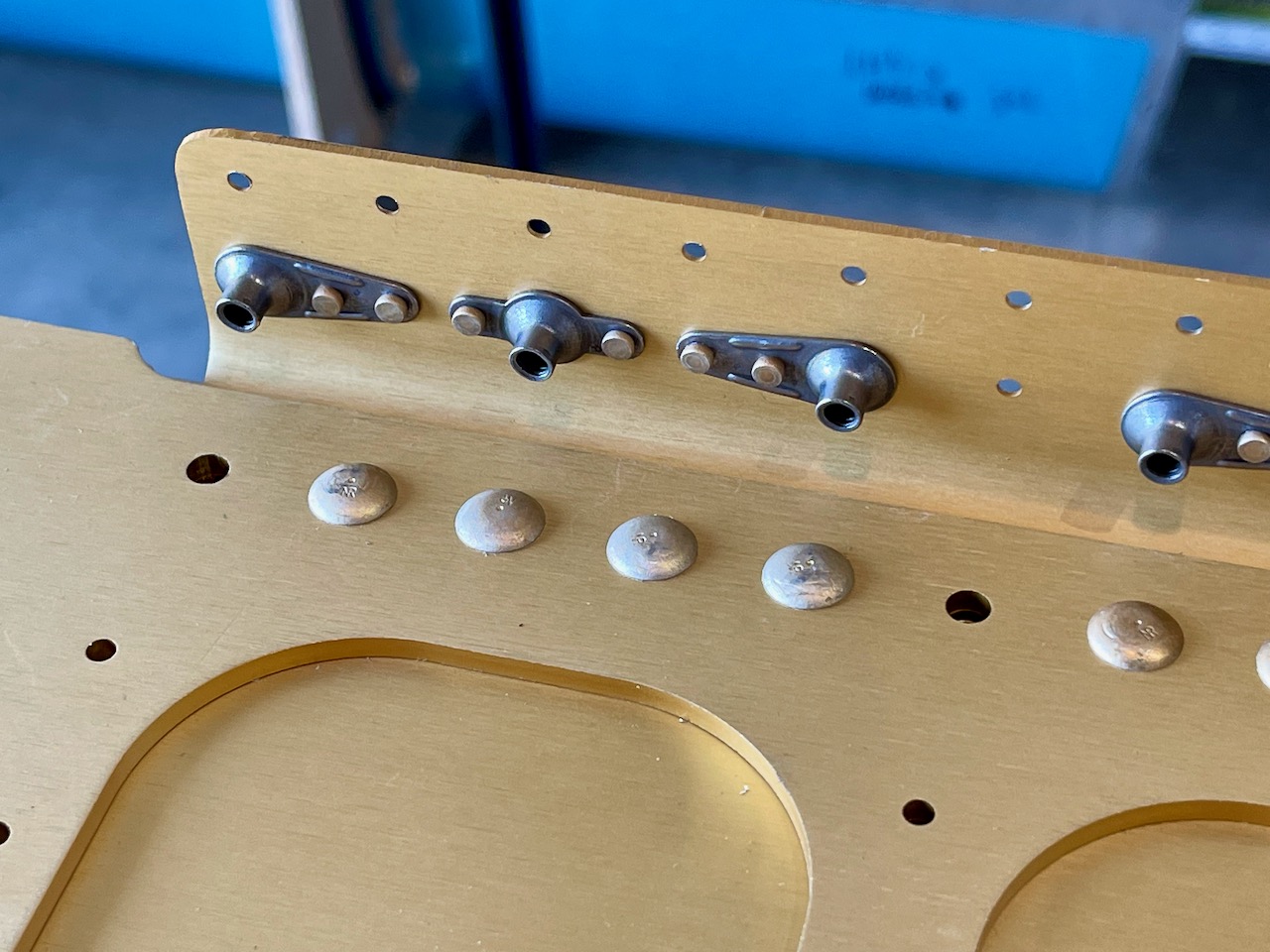

Today was spent riveting nutplates to the left wing spar. Two different sizes, one size for the fuel tank attachment screws (#8, two different styles) and another size (#6) for the wing inspection panels. Used the pneumatic squeezer for the nutplates which made for nice consistent rivets.

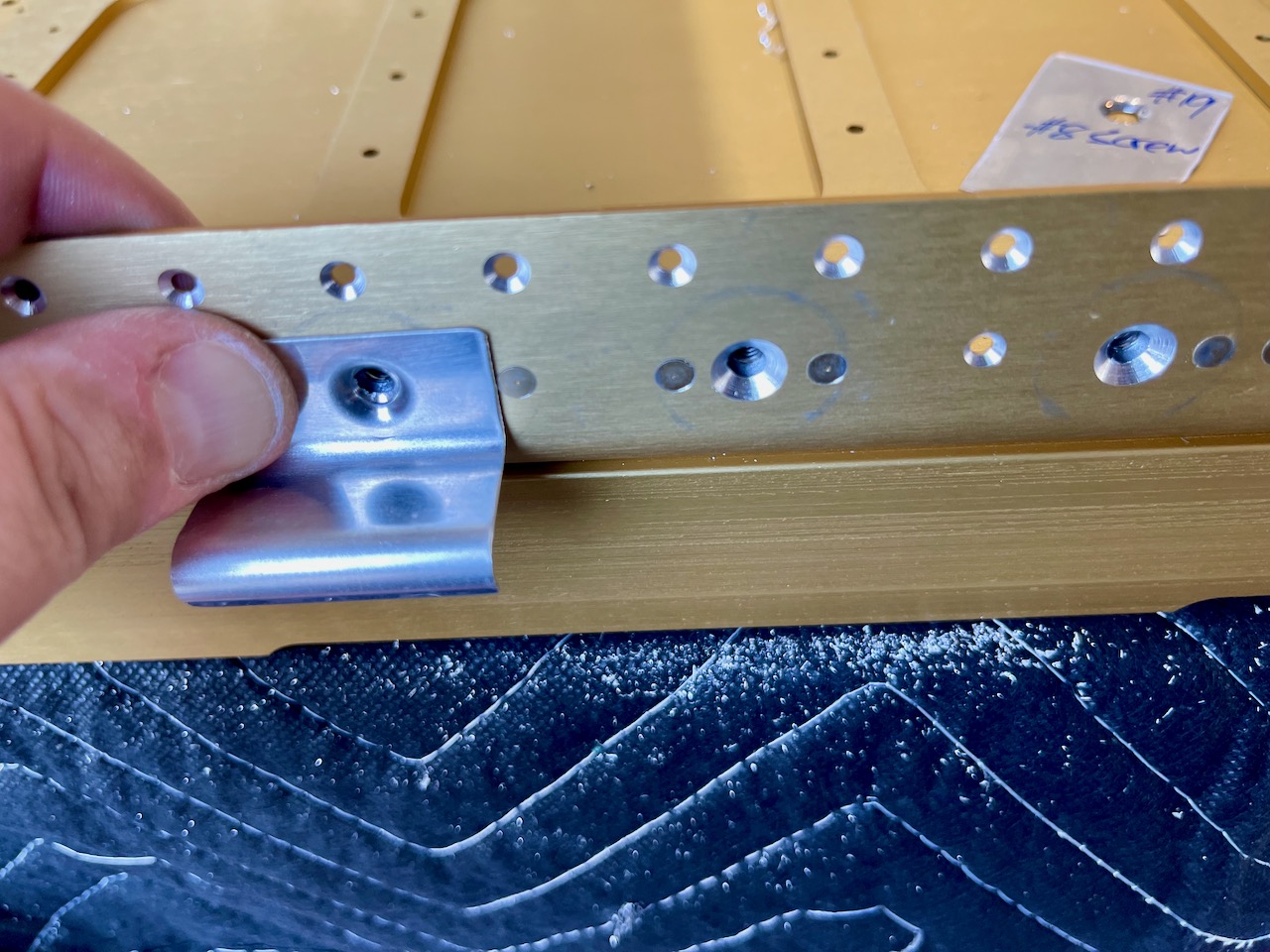

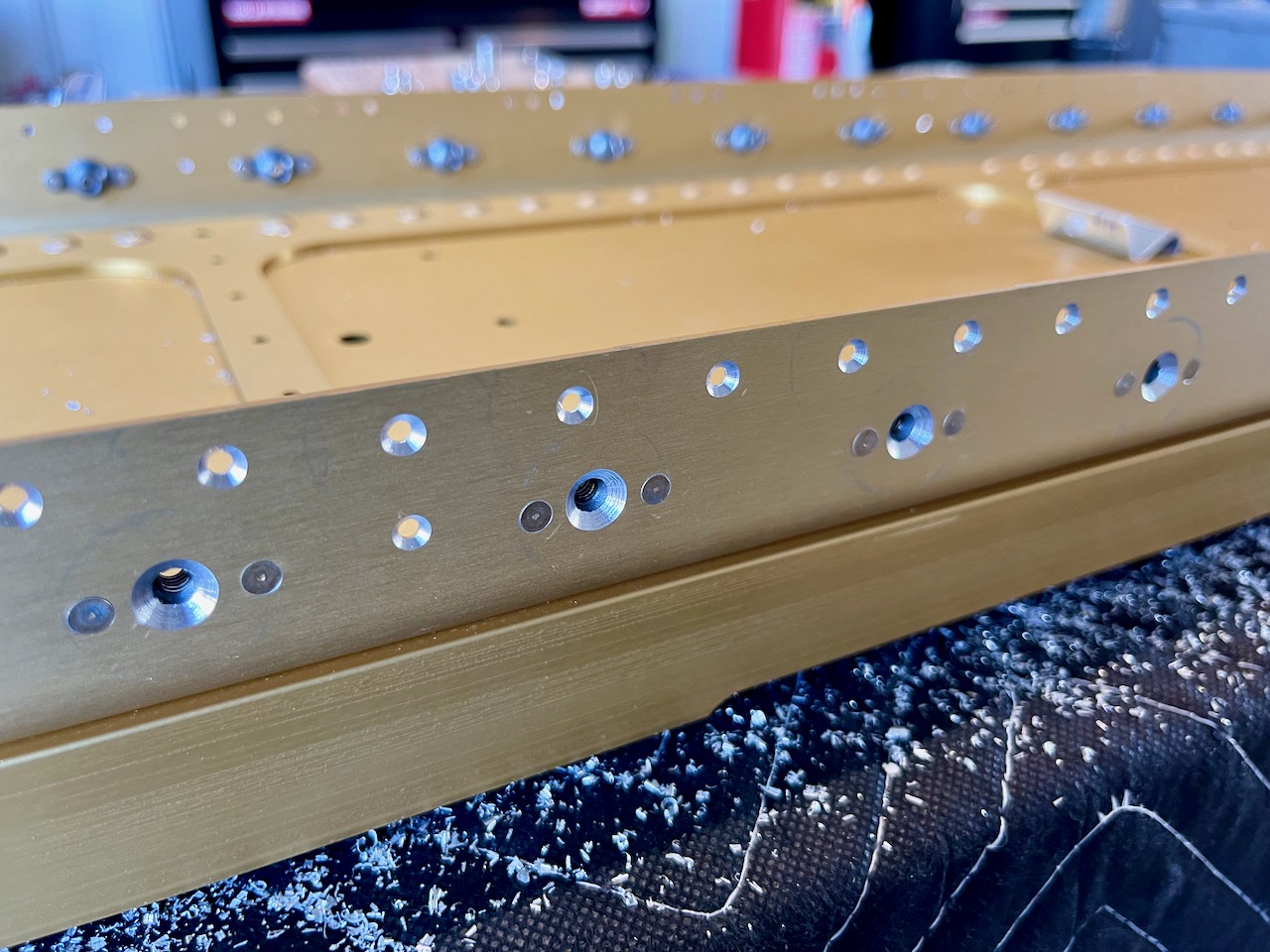

Then it was time to countersink the screw holes of the installed nutplates. These must be big enough to accommodate skin dimples for #8 and #6 screws, and the plans call for making a template for each of these. The countersinks for these end up being pretty deep but the plans also specify the maximum inner and outer diameter of the screw hole and countersink which is a good cross-check.

A hot, hot day in the hangar today, so took quite a few hydration breaks. This is a north-facing hangar, but it still ends up being warmer inside the hangar than the outside temperature on a sunny day… radiant heat from the roof. It’s a corner hangar too, and has a west facing wall. The outside air temperature was ~100F but we got ~107F inside, and even the parts got pretty warm to the touch (~105F!). The temperature of the west-facing roll-up door was 120F. Whew!