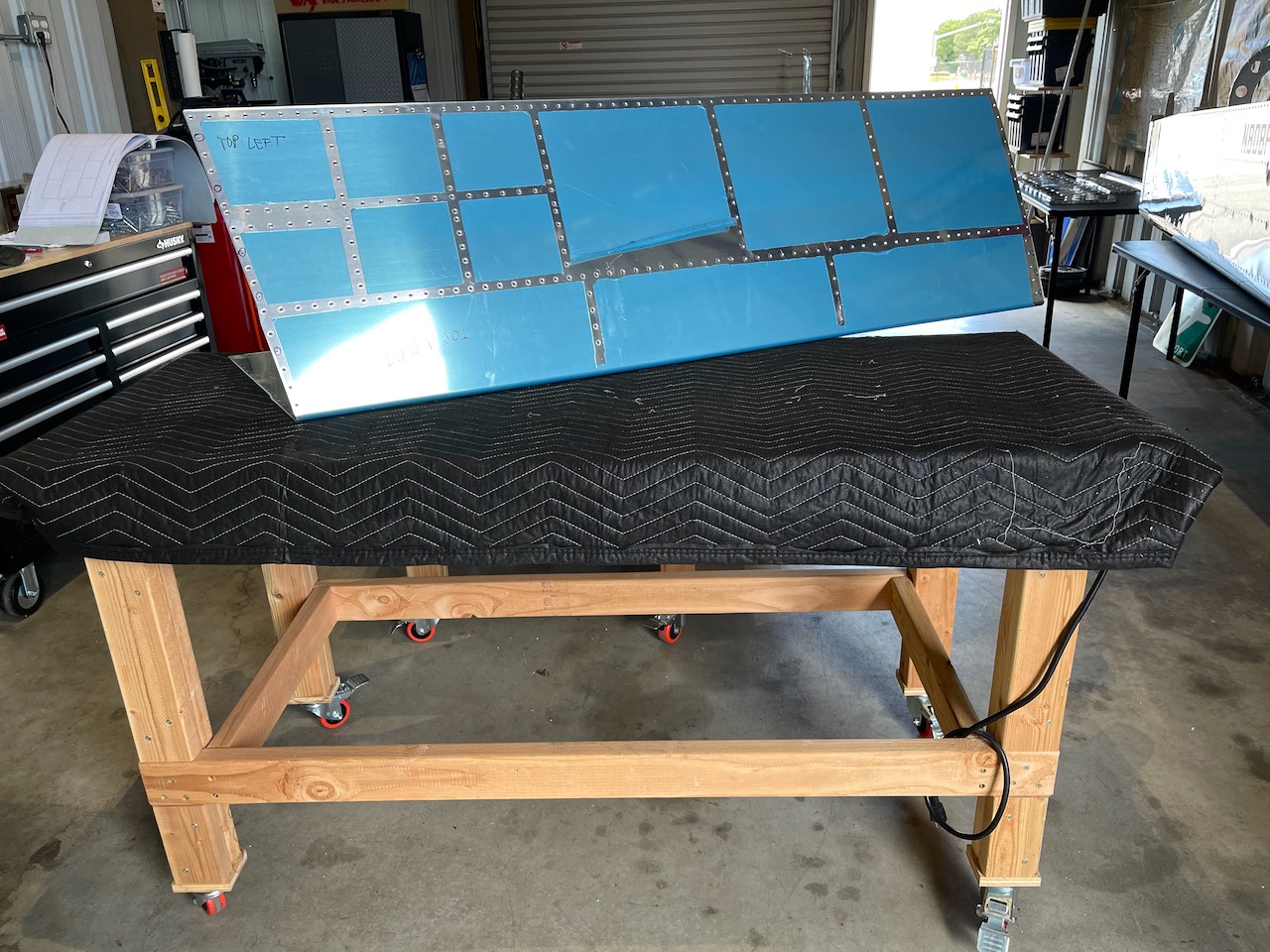

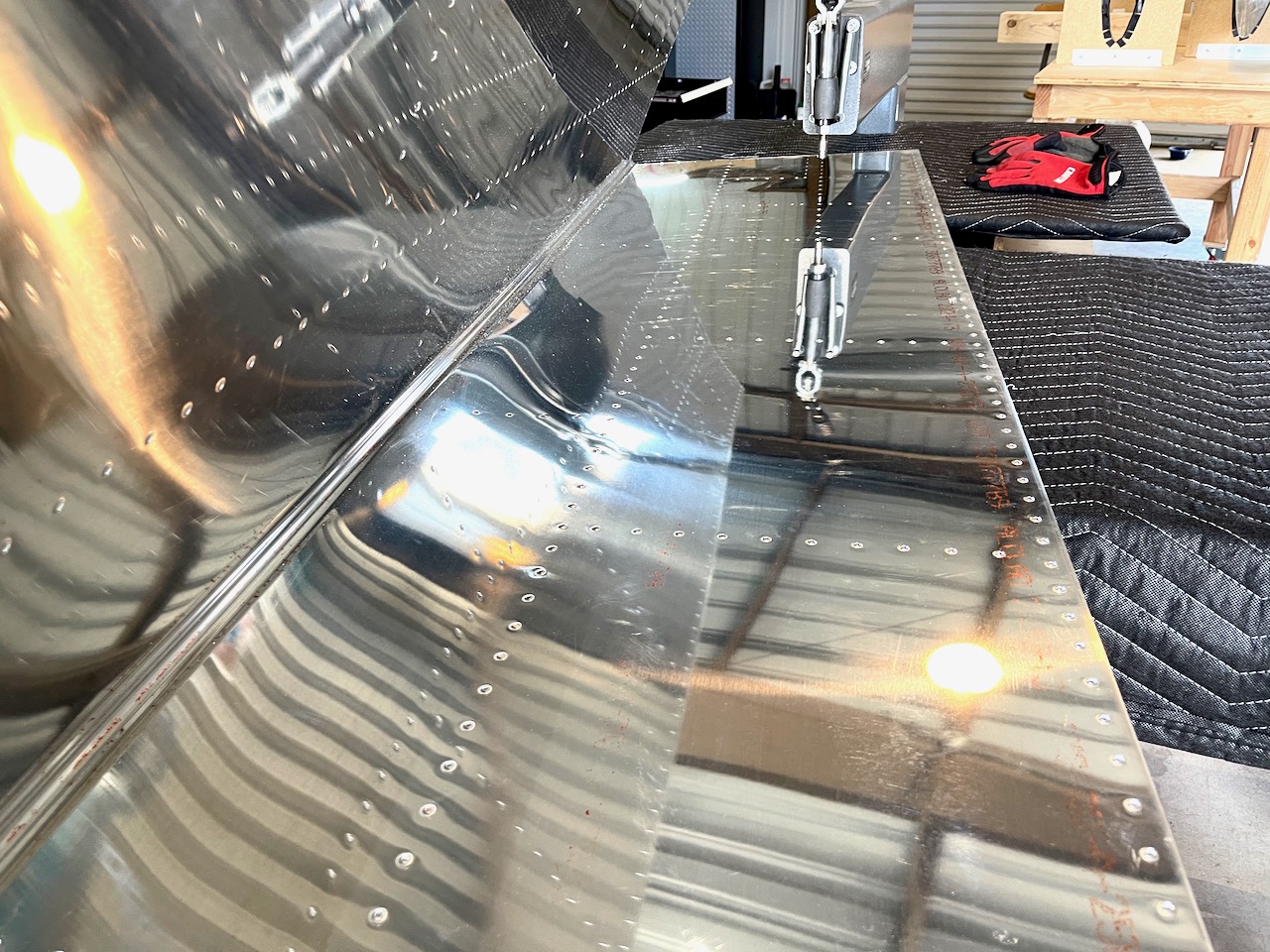

A light deburring on the holes of the outside skins of the horizontal stabilizer. They are already final sized, so no drilling was required, but the punched holes exit on the outside of the skins and were slightly rough to the touch. Then it was time to pull the DRDT-2 and dimple hundreds of holes.

I used a special dimple die set I got from Aircraft Spruce for those hard to reach places, and there were 4 places on each skin that I could not reach otherwise. The quality of those hard to reach dimples worked out beautifully.

Then just took a few parts and prepped and primed them. These will be the first parts to be riveted (other than the spar work already done).