Just a couple of hours today on riveting the doubler and spar caps onto the front spar. Four different sizes of rivets. Two had to be drilled out and replaced. Maybe not strictly necessary, but I find it easy to replace the AD4 rivets set in thick material like this. One had a somewhat deep “smiley” and the other had a very slight gap between the manufactured head and the work piece.

I was using my pneumatic squeezer, but it’s a little hard to fit on a flanged piece like this if the manufactured head is on the “inside” (which I had chosen since it’s the thinnest material). Have to activate the piston slightly, and then line it up with the rivet head… to easy to screw up. So I went ahead and ordered a “flange nose yoke” to make my future life easier.

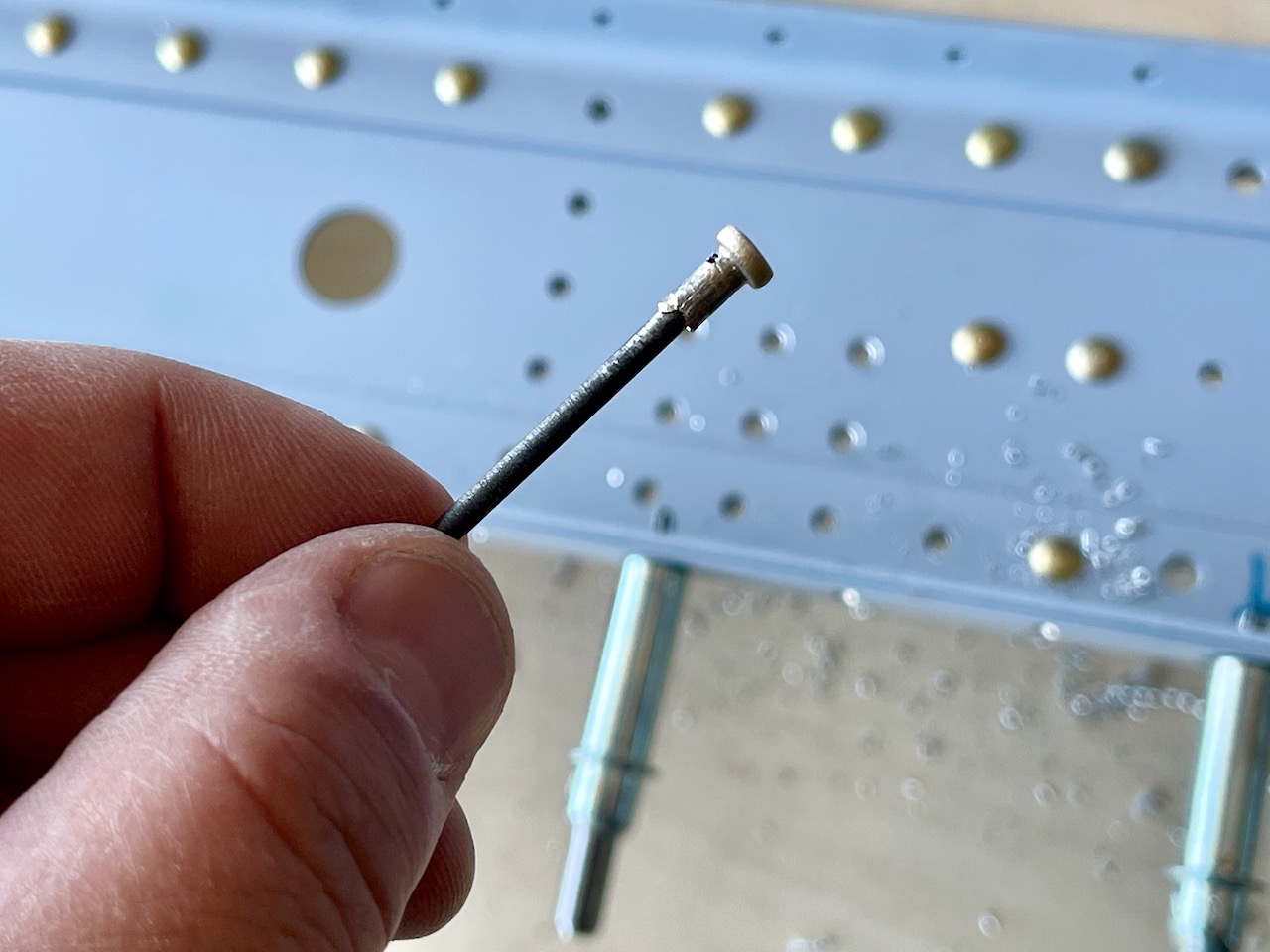

One picture included just to show the length difference between a set and unset rivet.