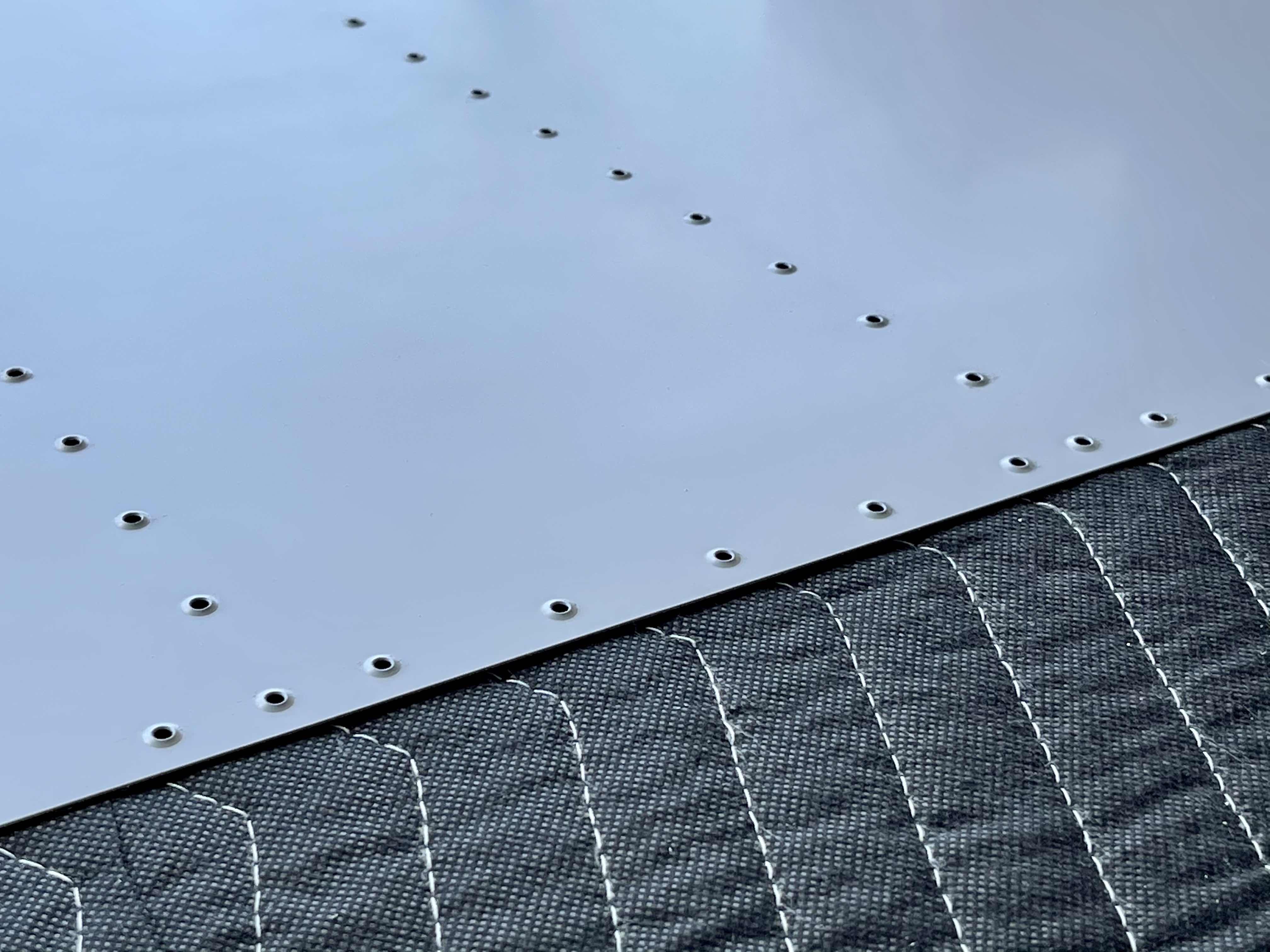

Started the day by finishing deburring of the last tailcone skin, the F-1074 tailcone forward top skin. This involved the edges and holes on both sides. Then dimpling of the holes that were ready to be dimpled.

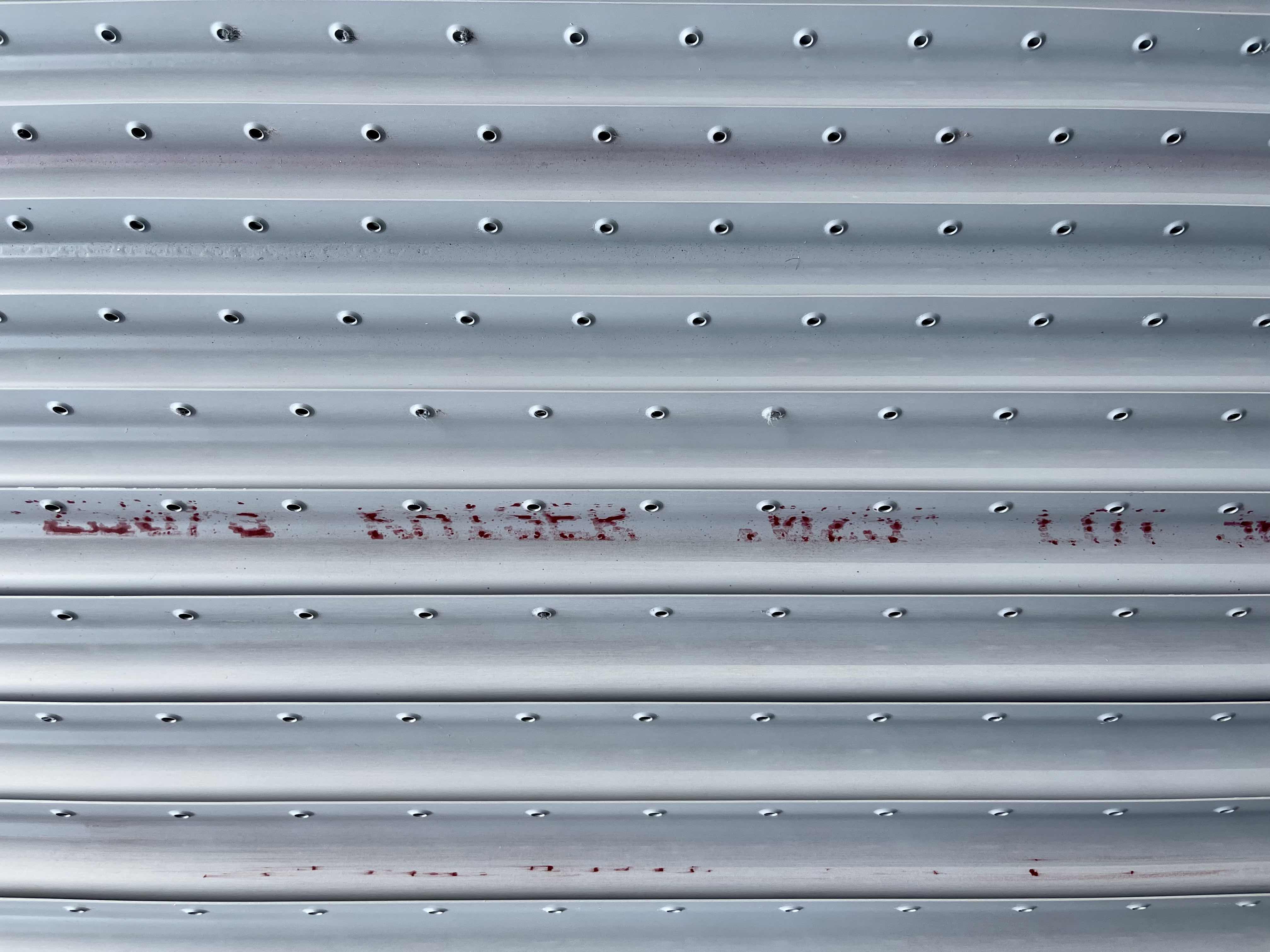

Then it was a lot of priming. This time, both tailcone top skins (inside surfaces), and 9 of the skin stiffeners that have been previously deburred and dimpled. The bottom 3 stiffeners had previously been primed already. The only slight challenge is making sure the parts were relabeled correctly after priming, since the acetone wiped out all the sharpie marks (and they’re all slightly different lengths, and previously match drilled).

So this means all the interior skins and stiffeners and bulkhead pieces (except for just one small one) are all prepped for final assembly.