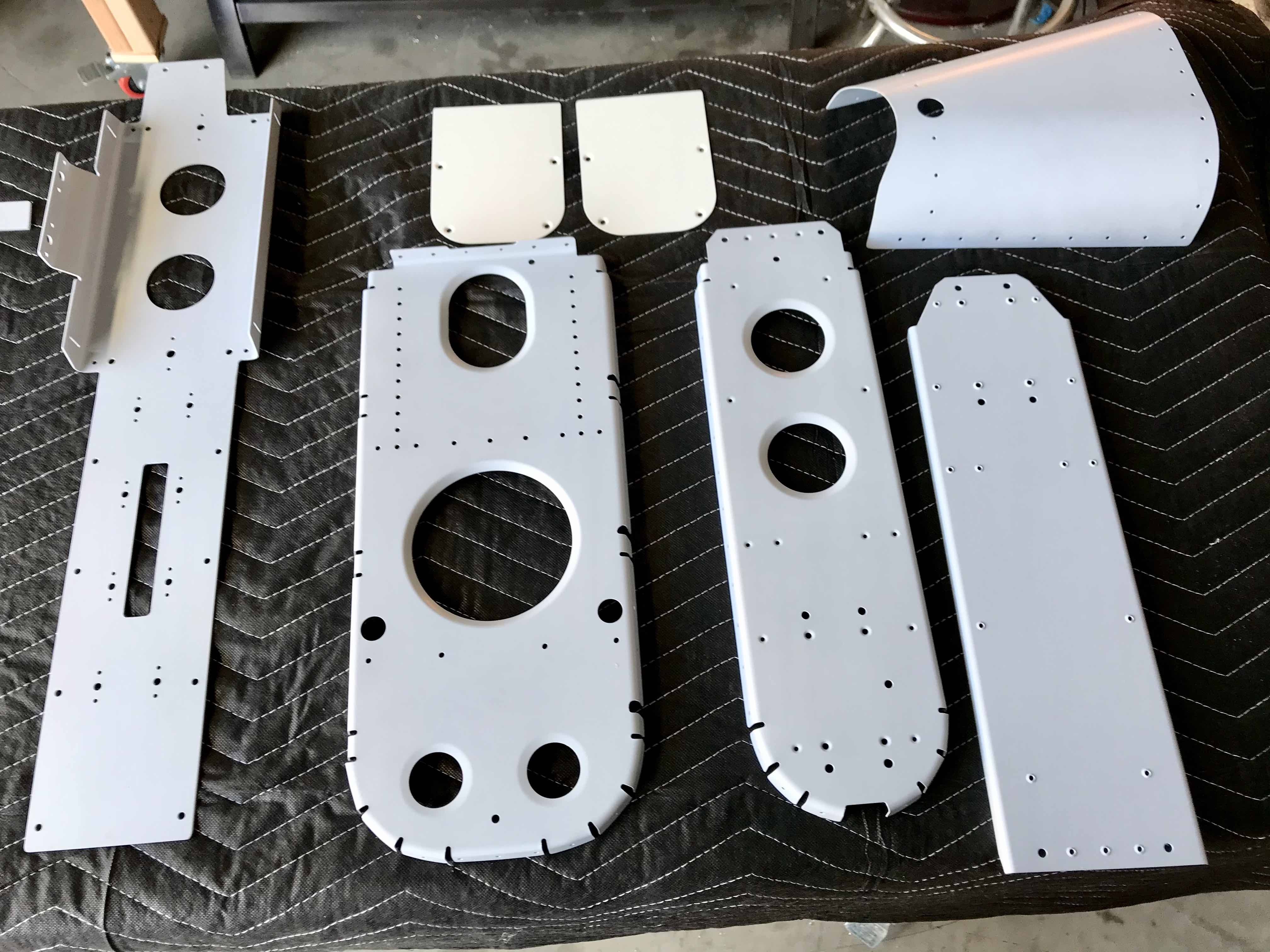

A mixed bag of deburring, countersinking, priming, and riveting nutplates today on some tailcone parts. The nutplates are literally mixed bags in their own right.

The small aft bulkheads were deburred, along with a lot of the accompanying brackets, stiffeners and doublers, etc.. Then very lightly scuffed with grey Scotch-Brite, cleaned with acetone, primed, and shot with a heat gun to quickly flash the primer for handling (turn-over for the other side). Just for fun, I shot the inspection panel exteriors with white enamel. I have no idea if there is even going to be white on the exterior of my finished plane.

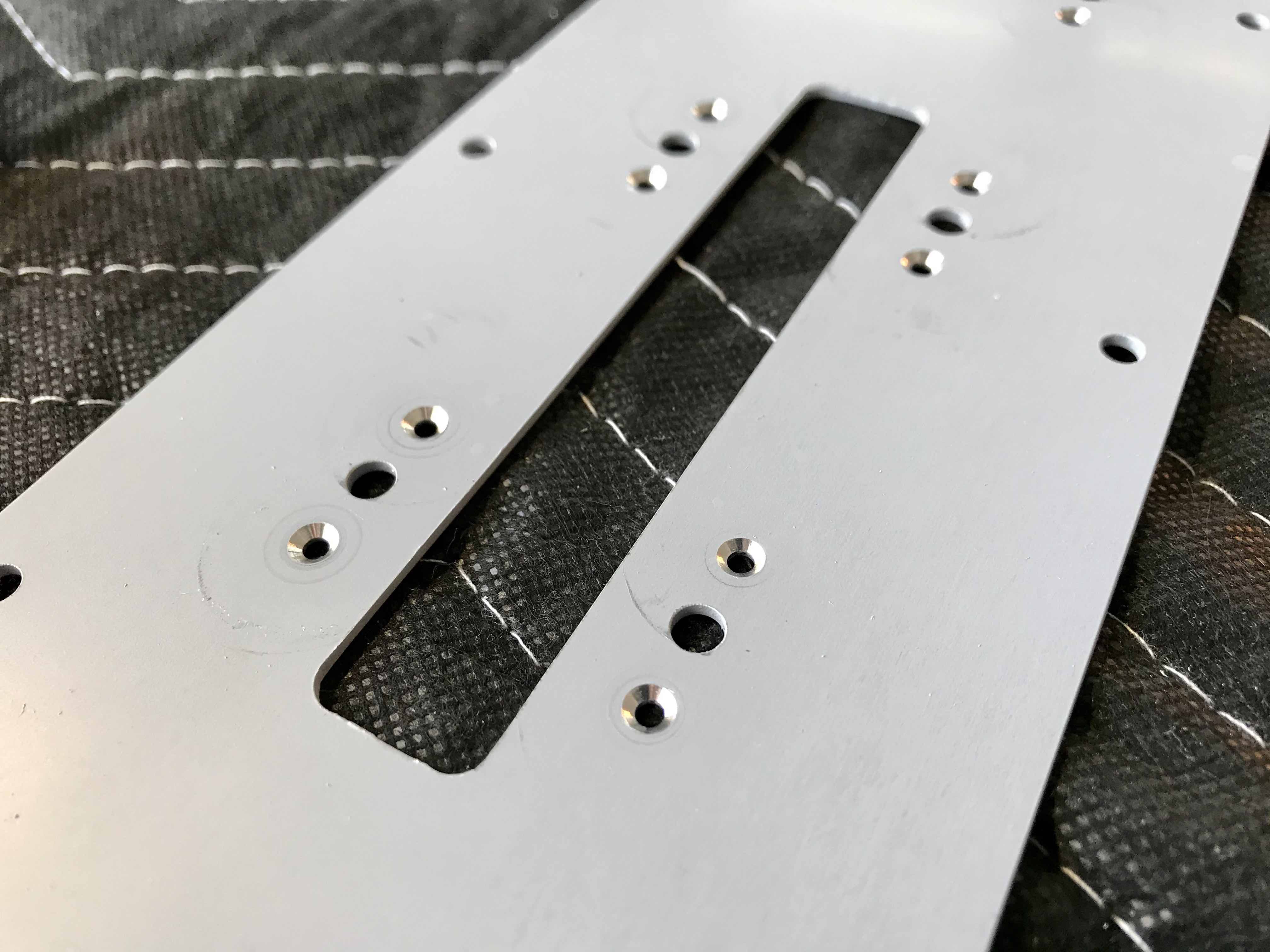

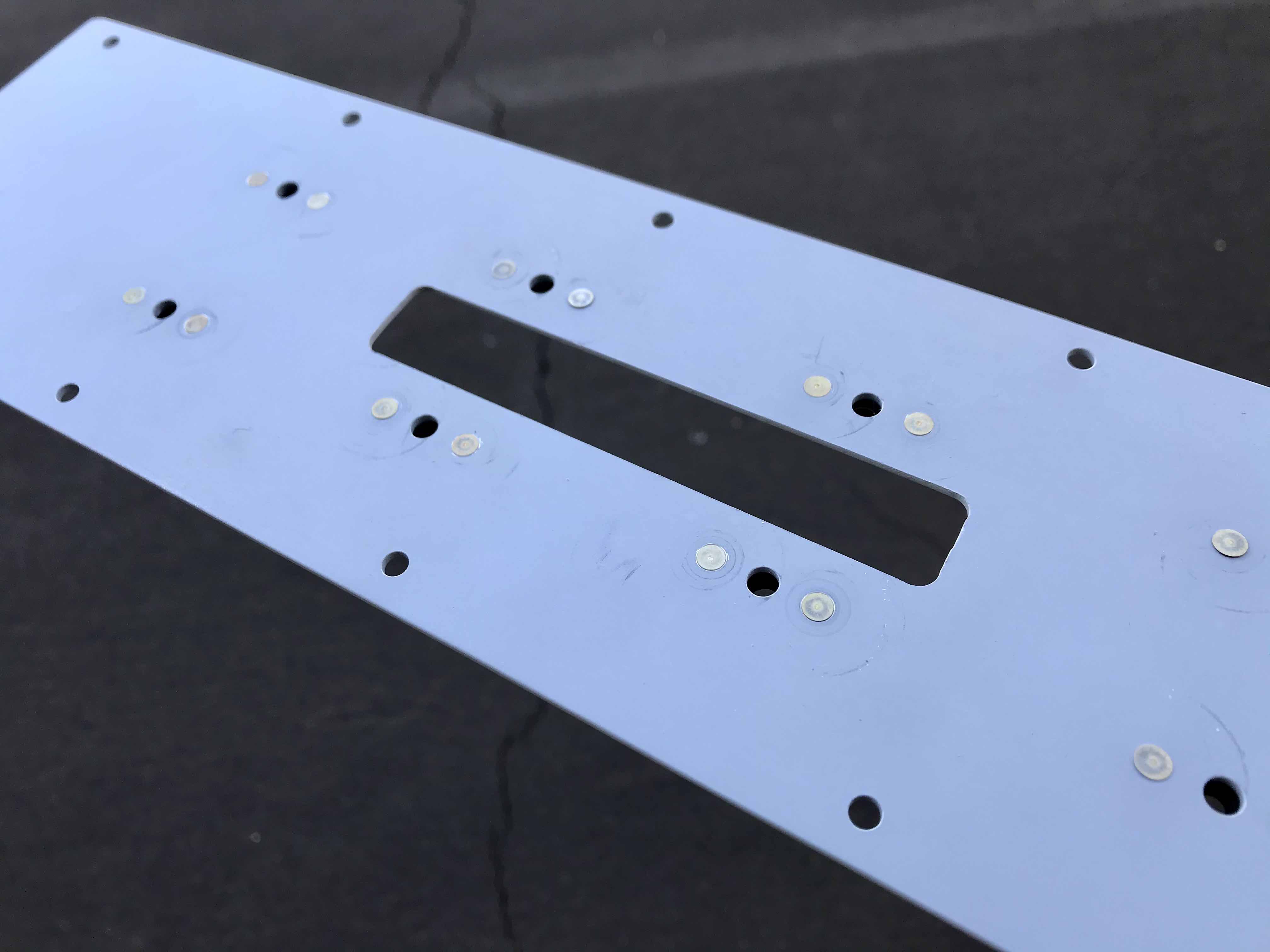

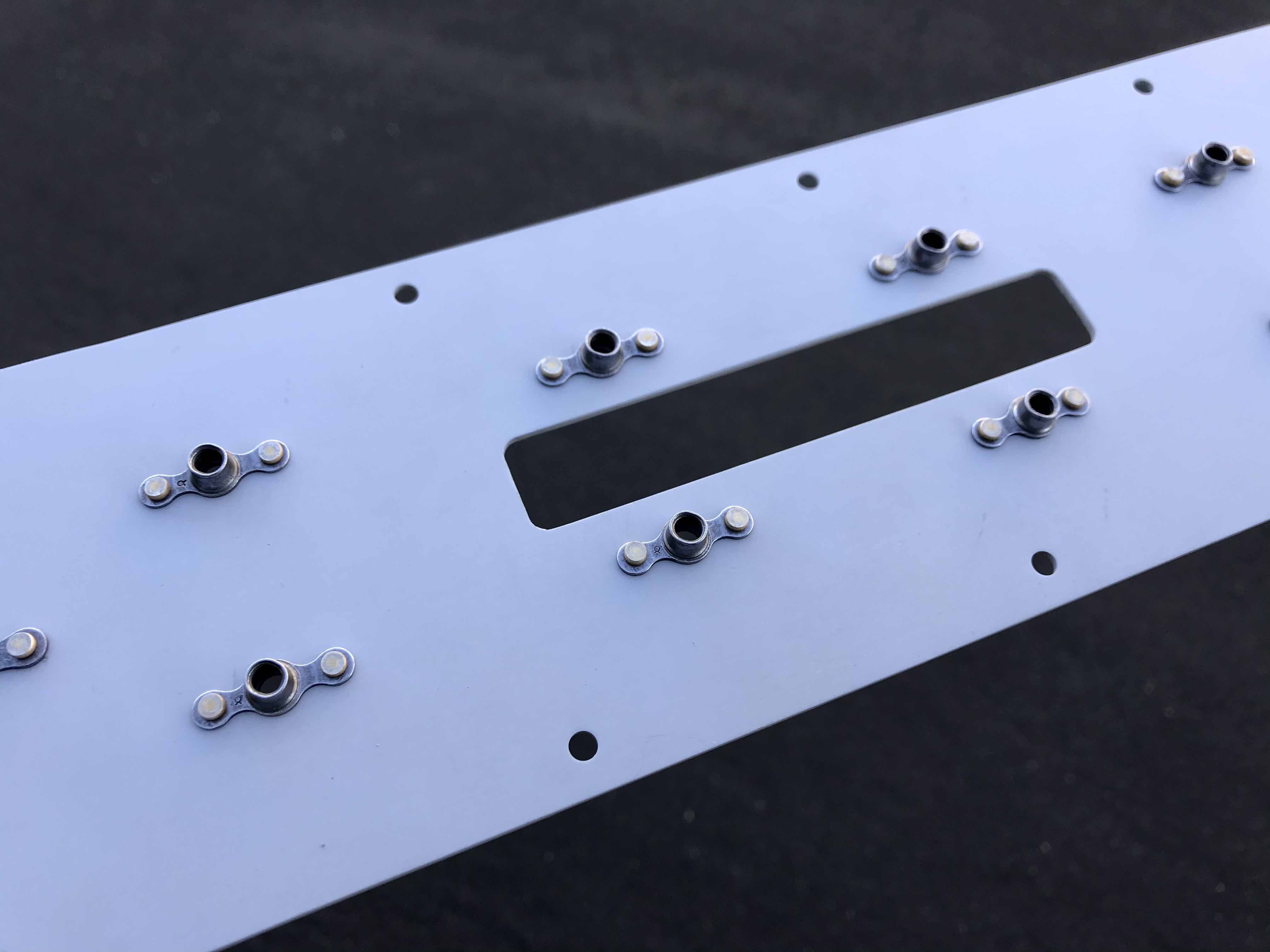

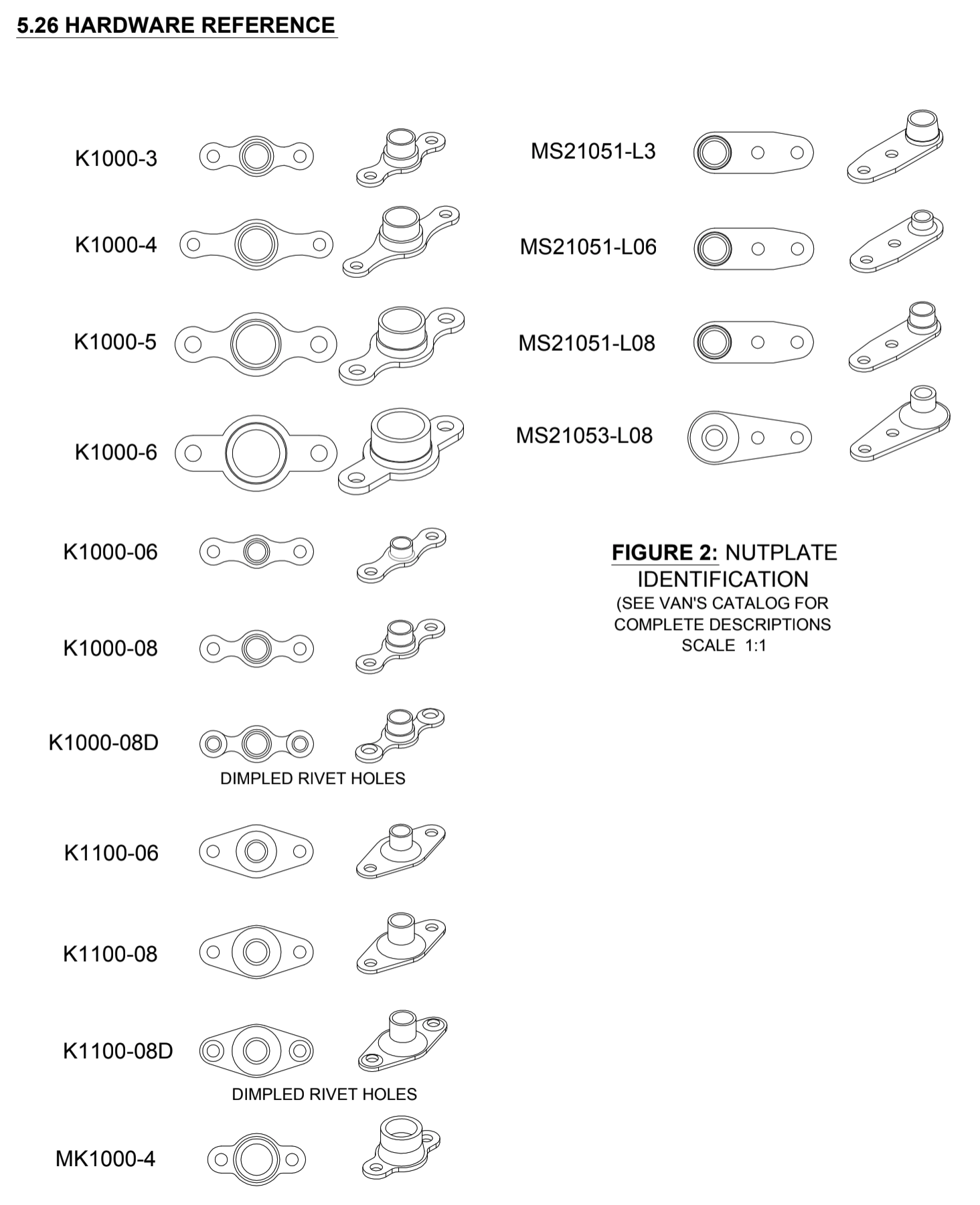

Then some additional countersinking that I forgot on the thick bellcrank/battery mount piece, and riveting of nutplates with the pneumatic squeezer. Part of that job is digging out the appropriately sized nutplates from the correct of several baggies that’s mixed with nutplates of different sizes. Fortunately the mixed bags contain varieties of nutplates that are quite different rather than some of the harder to distinguish variations. And of course, there’s a cheat sheet in the manual to help identify what a particular nutplate is supposed to look like (to scale). But a pro-tip is to keep your packing list handy which identifies which part# is in which baggie.