Next step in the plans was to attach the shoulder harness anchors (F-636) to the longerons, but I had to skip because those parts are backordered. However, was able to final drill the two aft inspection plates. Will have to revisit to add those anchor plates after reassembling the tailcone…

Because next was a total disassembly of the tailcone! Now that all of the holes have been drilled, all the parts must be prepped for final assembly… those prep steps will include the usual deburring, dimpling and in my case, priming.

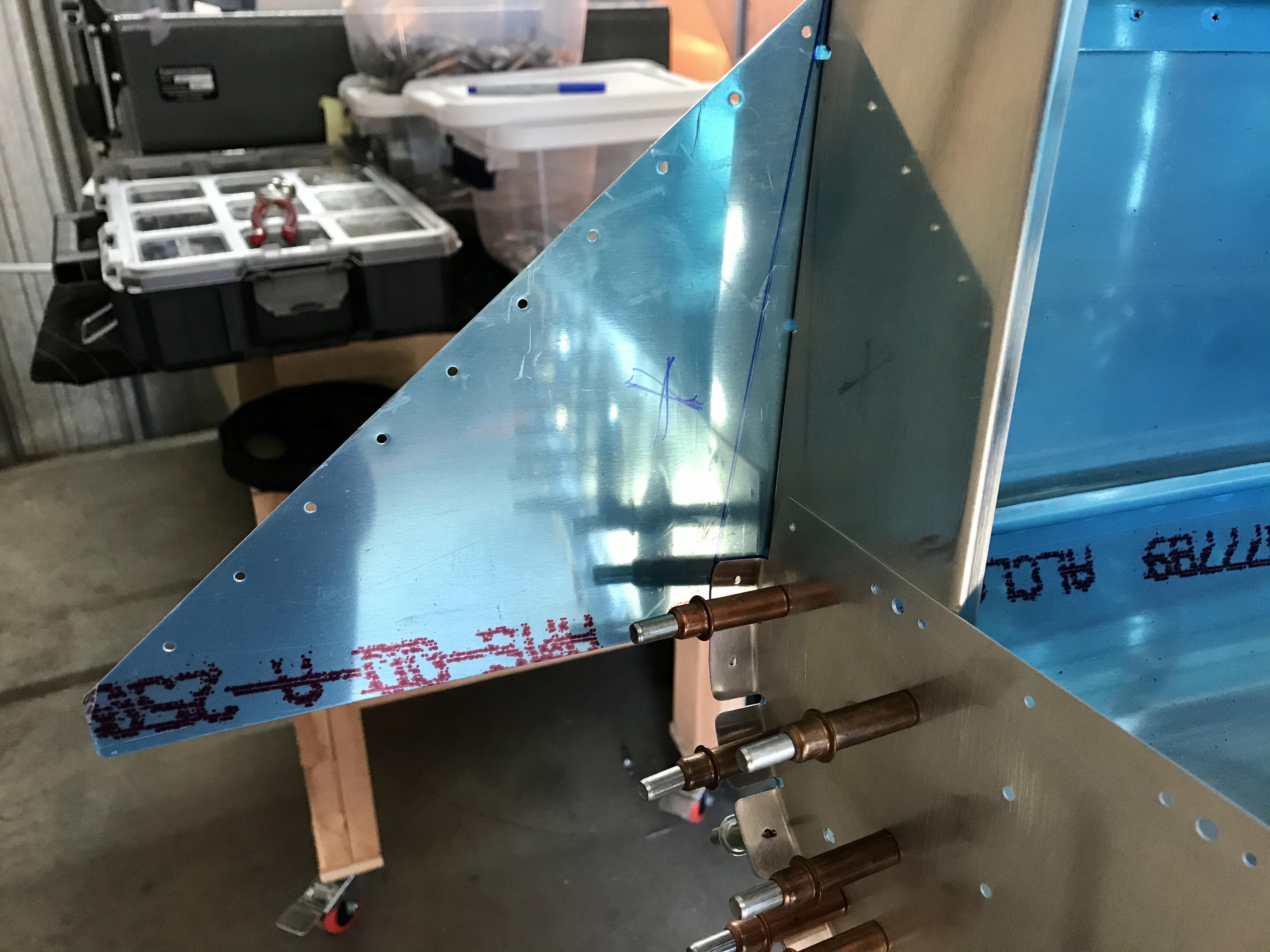

But first, there was a little triangle of the right side skin that needs to be trimmed off. This little tab is only required on the left skin, I suspect having it on both is just so that a single punch template can be used for both skins.I started with a cutoff wheel on a rotary tool, but quickly realized there was enough access for a pair of snips to do the cut, plus a little filing of the edge.

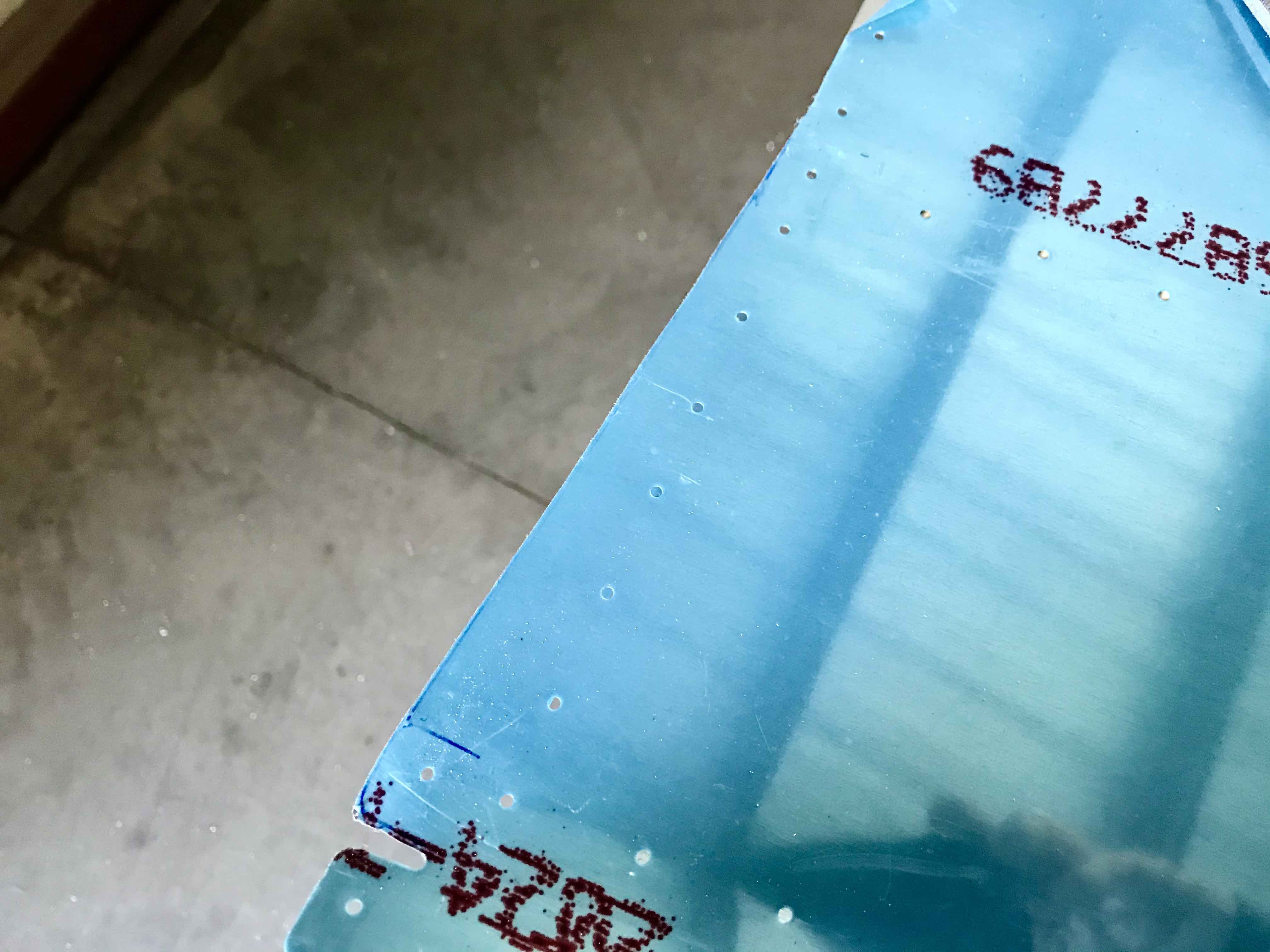

Now came some of the parts prep. One step was to use a uni-bit to drill a hole big enough to accommodate the tail tie-down bolt. Then came some dimpling and countersinking of some of the bulkhead pieces.