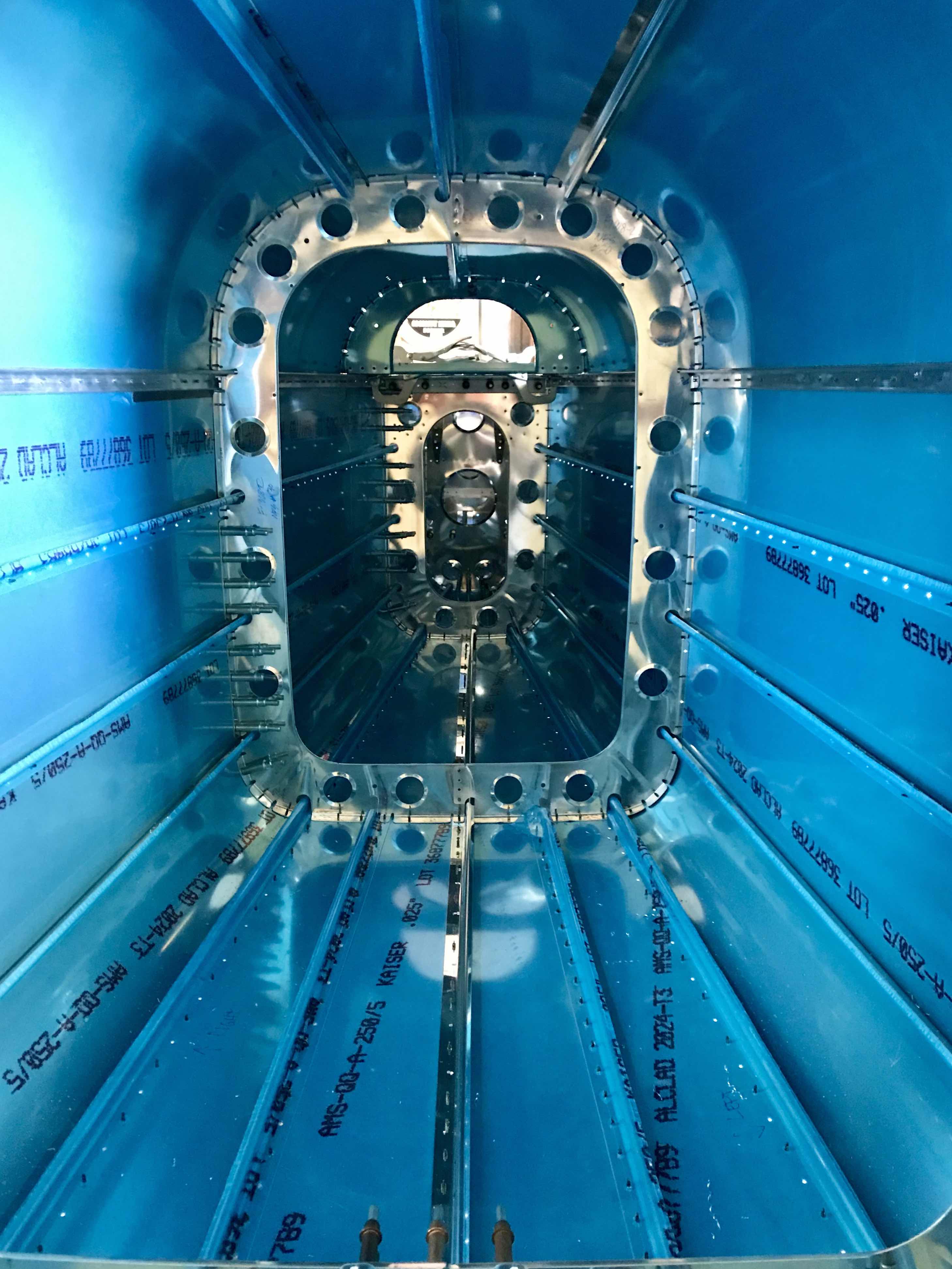

Today started with the time-consuming task of match-drilling the longerons to the skins. The angle aluminum longerons are a little thick, so my drill bits got a workout. My only concern is that the plans called for a 3/32″ bit, but the skin holes are already final sized to #40 so not sure if the longeron holes are completely centered, or if even makes a difference since the delta is so tiny.

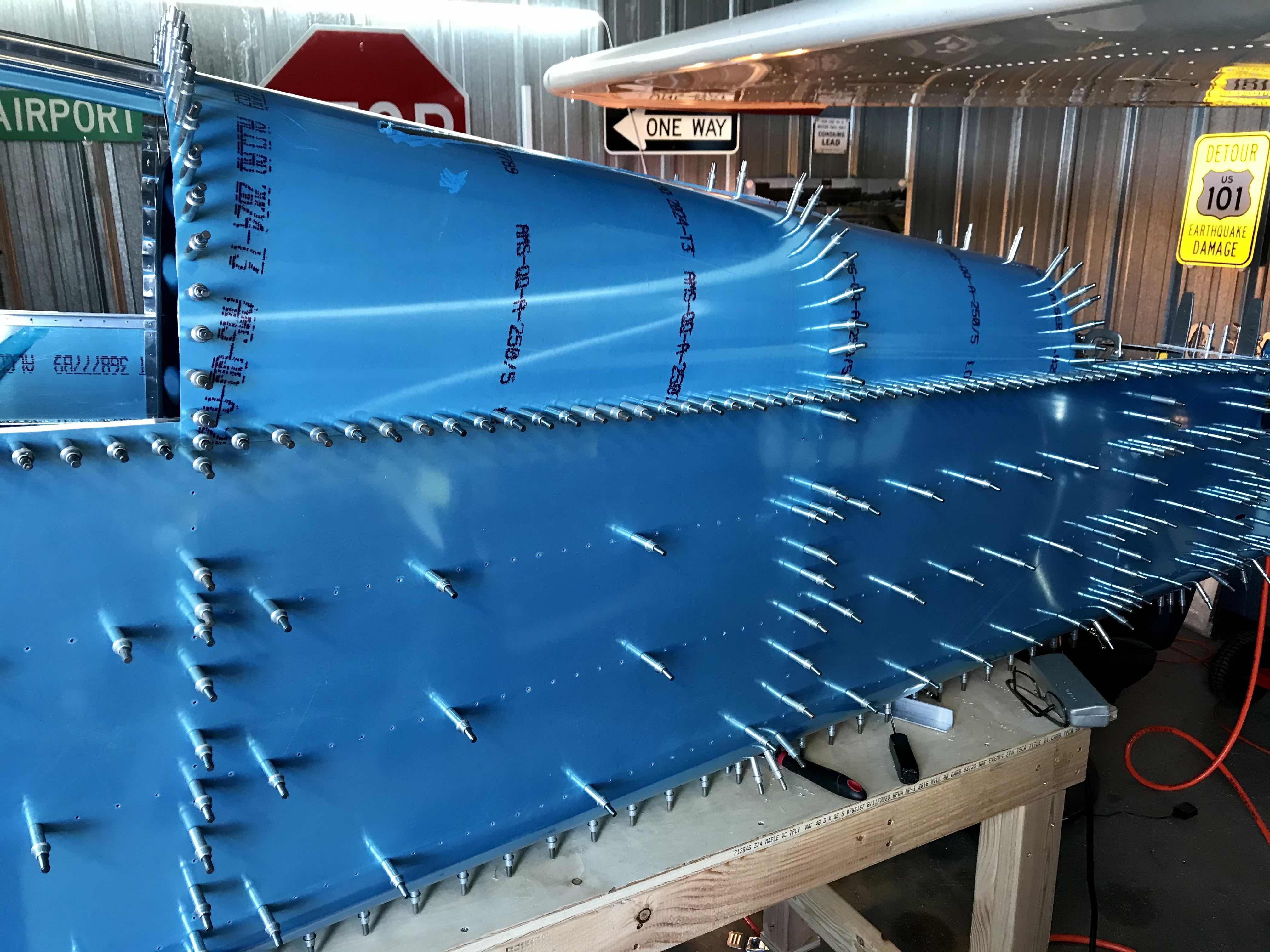

Then came the step of putting the first large tailcone top skin and clecoing in place (after sliding three stiffeners into the appropriate bulkheads). These pieces are not pre-curved, so it took a little force to get them to conform to the contours and get clecoed in place. End results was great, the portion of the skin that overlaps the side skins and longerons was successfully clecoed on both sides, and it fits nice and tight against the side skins.