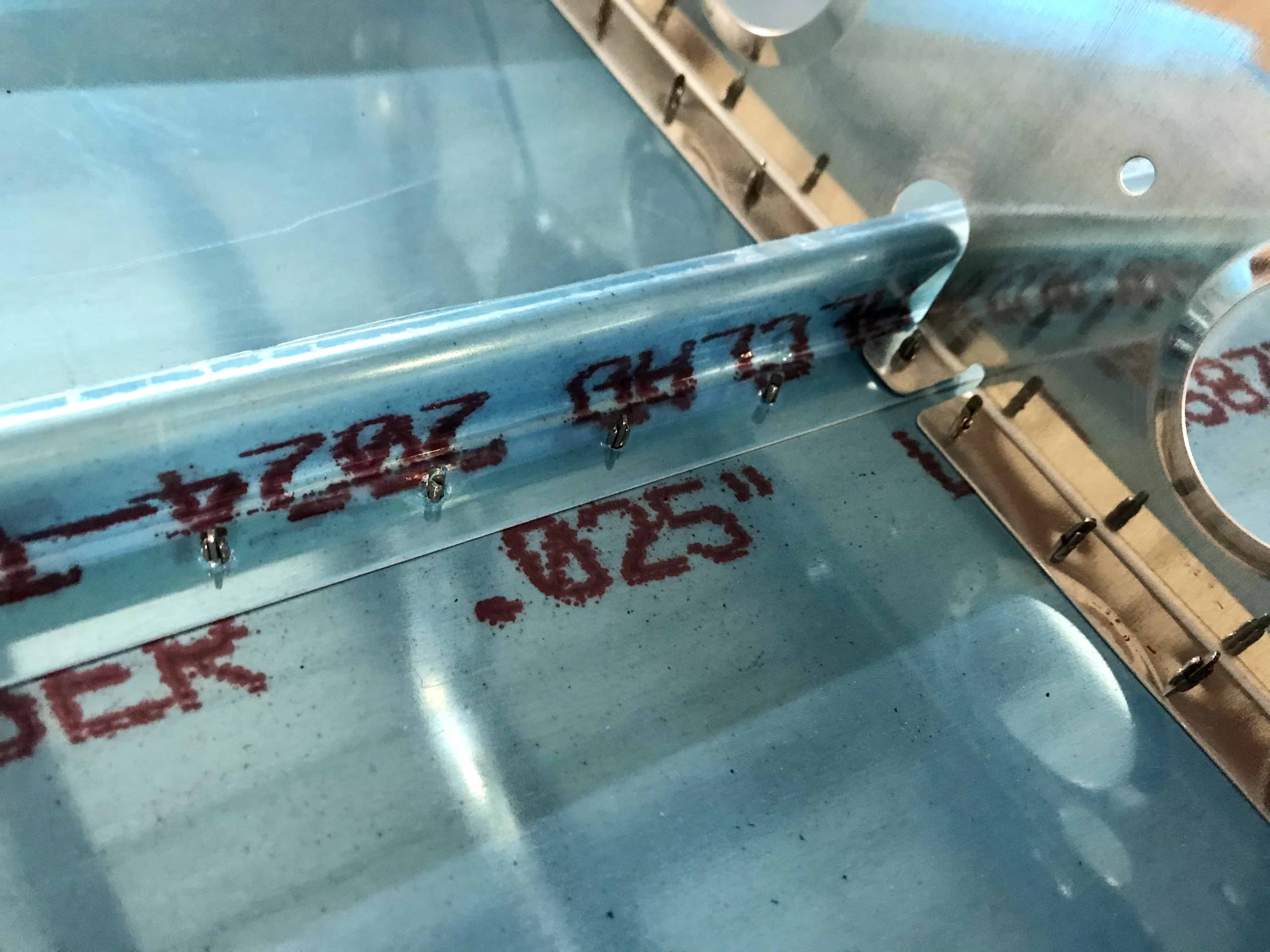

First step today was “using a rubber mallet, strike the longeron firmly near the bend mark.” Yeah, so basically you have to bend a long piece of aluminum angle into a “just under 2 degree bend”… It was easier done than said actually. Two total were required, one for each side. I was surprised how closely I came to the necessary bend on the first attempt. This works out to approx. 3/4” bend at the end. This allows the longerons to sit along the edge of the side tailcone skins, so the good news is those skins serve as a template.

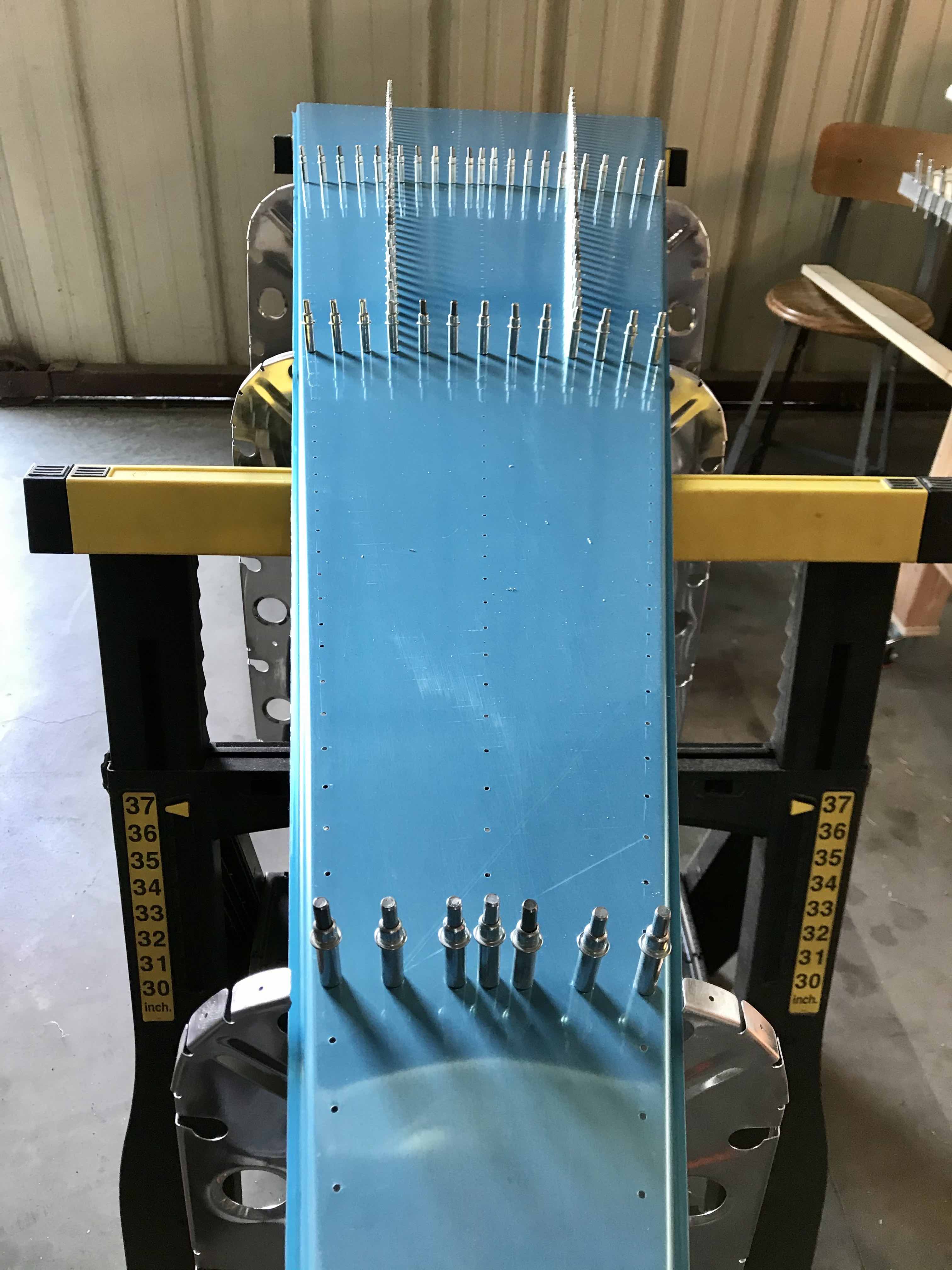

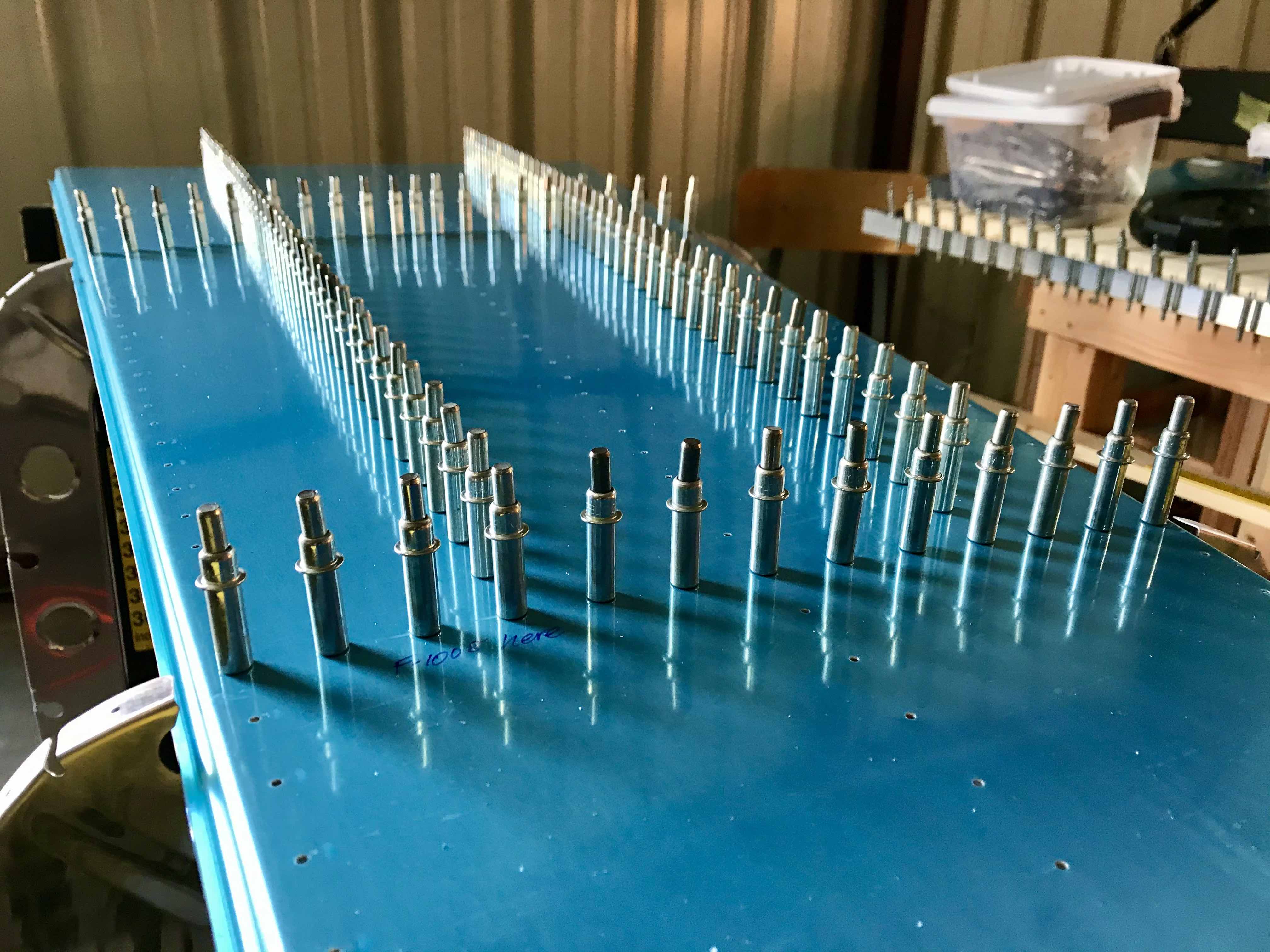

The rest of the session gave the impression of an awful lot of progress in a short amount of time. It will all have to be disassembled soon enough. The day’s steps involved attaching the bottom skin to three of the bulkhead pieces, and inserting the J-channel stringers, and match drilling them along the centerlines that I had drawn on them in a prior step. Easy work once I figured out how to orient the J-channels in the cutout slots.

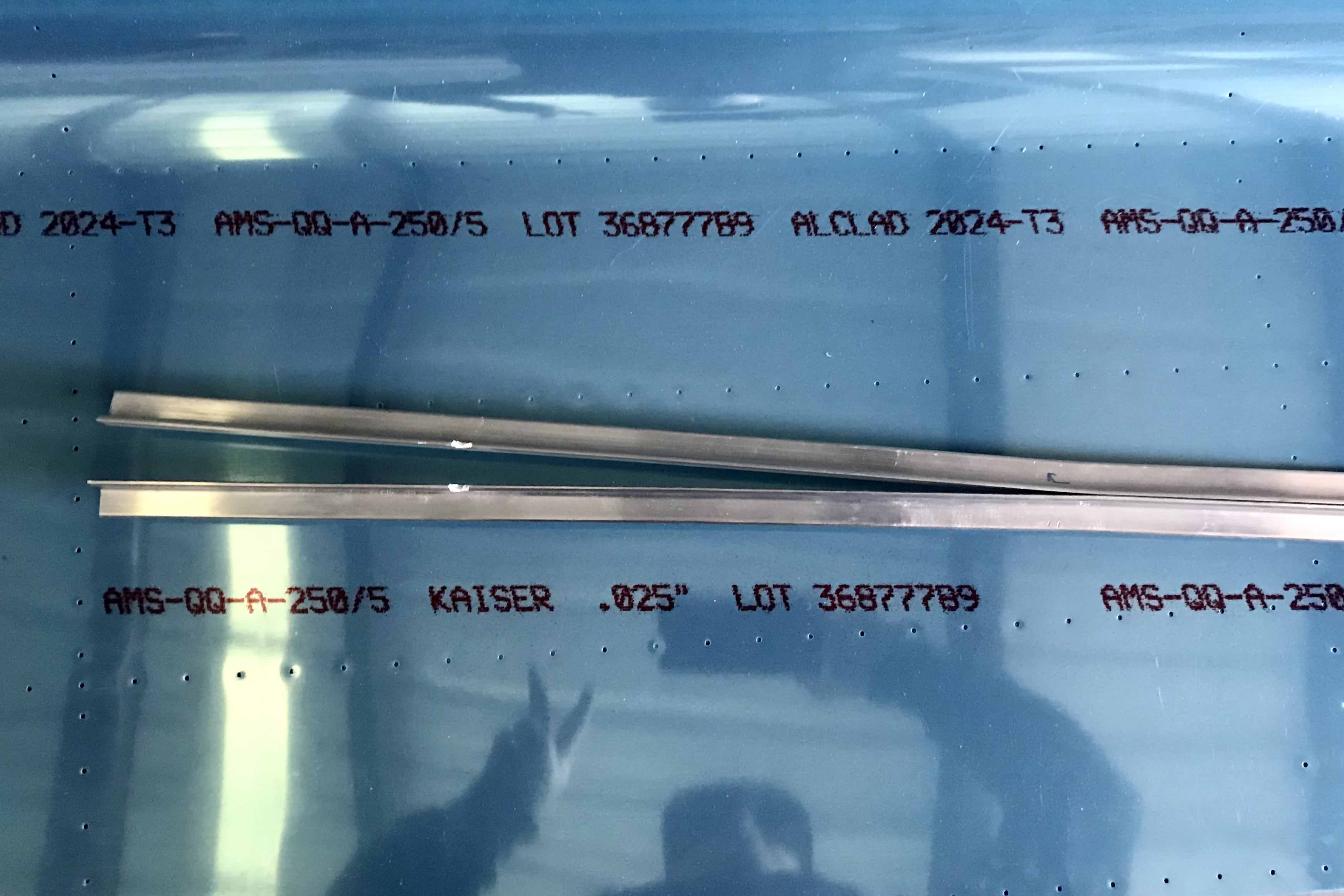

Then, the next step is to insert three more J-channel stringers on the side (these are the long ~90″ ones), then attach the right side tailcone skin and cleco everything in place. I had just clecoed the top skin and the smaller bulkhead, before I called it a day. Looks like a lot more J-channel drilling in store for me next.