Zipped up the left and right rudder skins today. They really do meet just like zipper, just a little more stressful…

First of all, eagle eyed readers of the last post may have noticed that I forgot to trim an edge off the new stiffeners before riveting. So I started by doing the trim in place with a rotary cut-off wheel, which left a slightly crude cut, since I opted for a jagged cut versus getting too close to the skin. A few minutes with some files, then varying grits of sandpaper cleaned these edges right up and made them smooth. A little shot of primer finished the job.

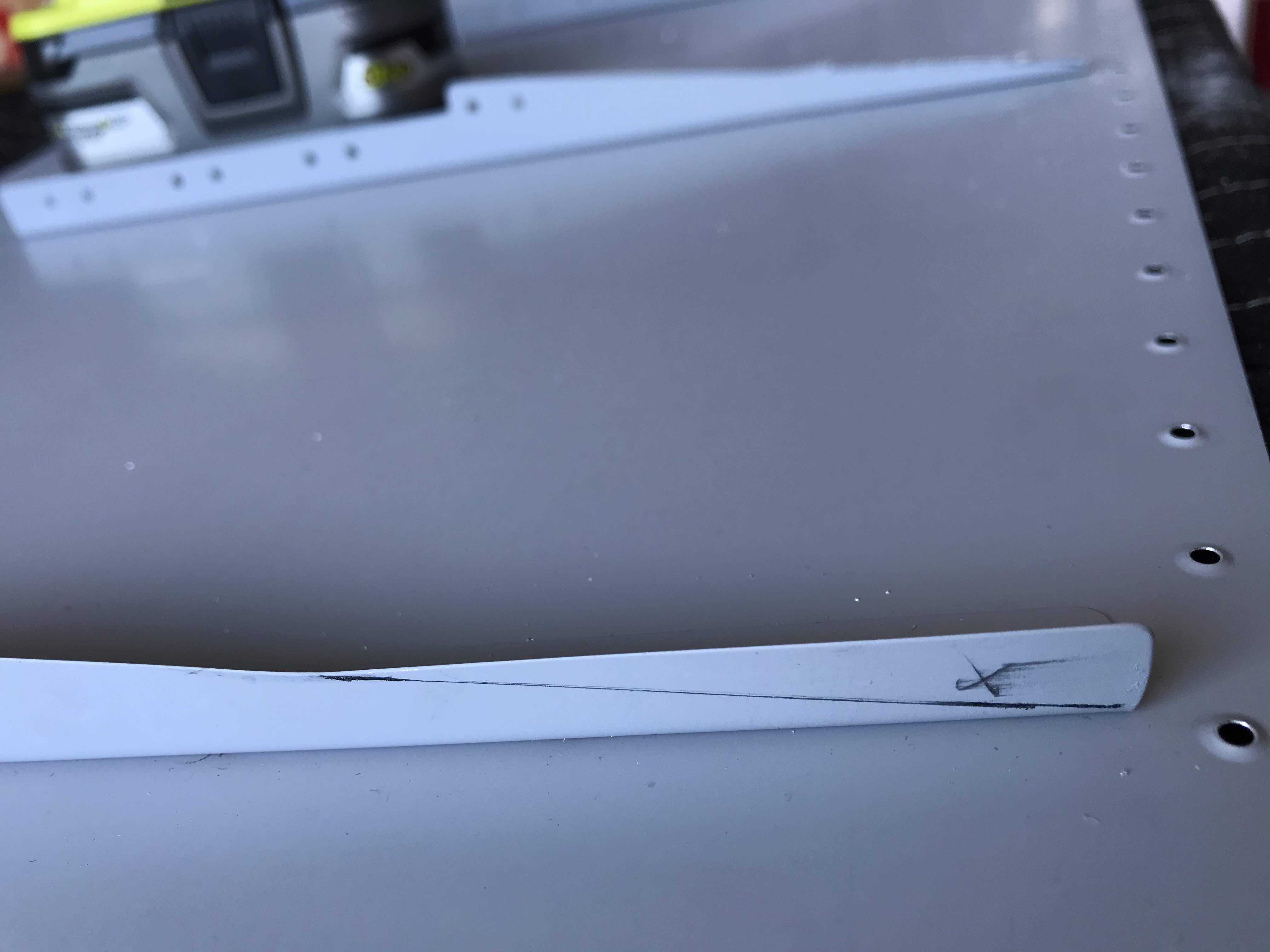

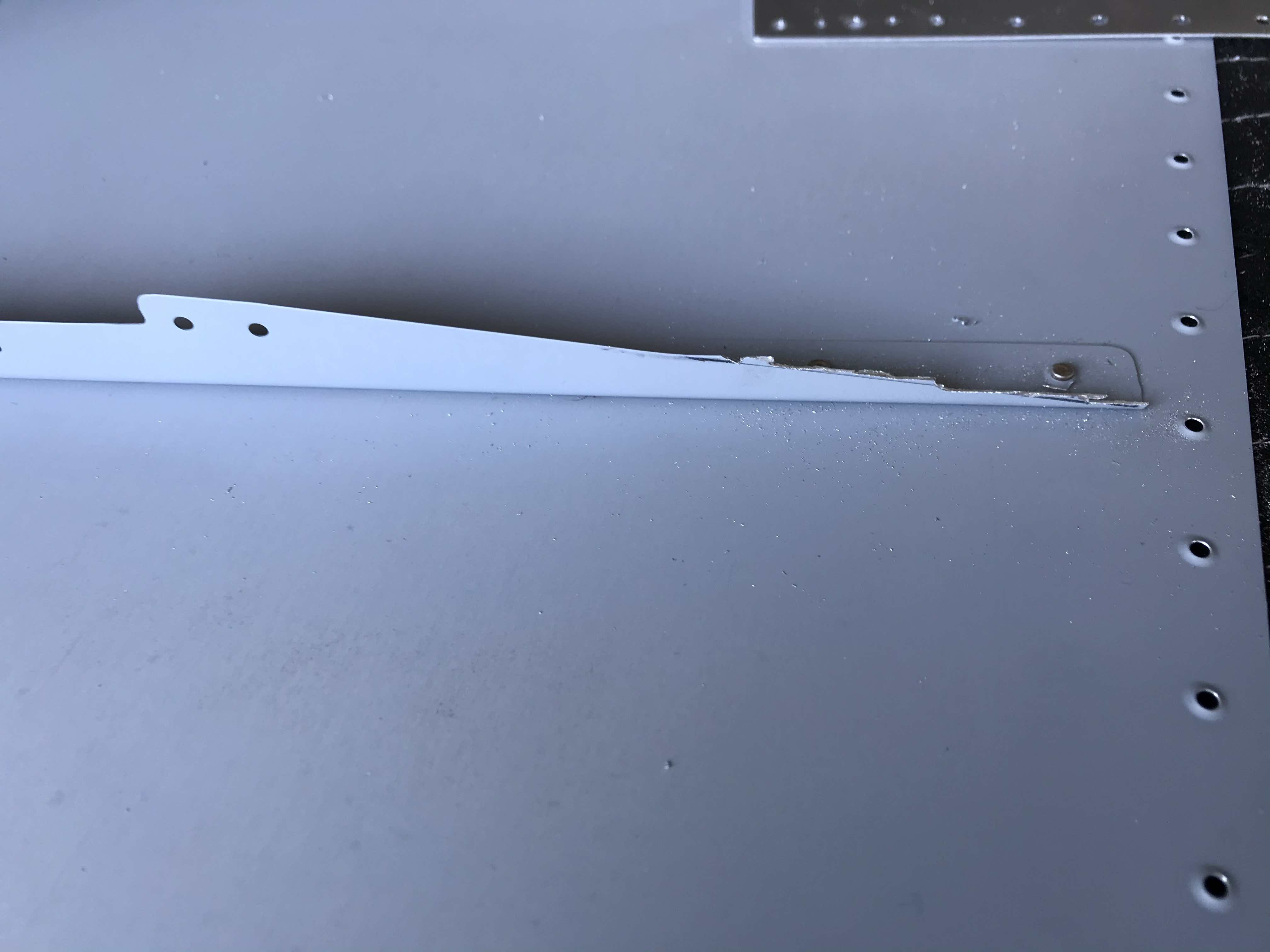

Then it was time to attach the trailing edge wedge and marry the skins. Directions call for either a tank sealant substance or double sided tape to hold the wedge in place. I have a feeling this is primarly to hold it in place when it comes time to back-riveting the trailing edge, since many clecos have to be removed to do this. I, however, am going to use a rivet squeezer with an special angle set to drive these rivets, so a little unsure if the sealant/tape is necessary as I will keep adjacent clecos in place while riveting. Well, I had a little container of tank sealant so I thought I’d give it a try. It can’t hurt (much) and may help keep the edge tighter.

Yes, it’s nasty stuff, like everything I’ve read. Super thick, super nasty. Could not apply it very well because it was too thick. I was trying a foam roller. Ended up just grabbing some in my gloves, and rubbing the trailing edge wedge through my gloves to just leave a thin layer behind.

Now the skins have to be zipped within the couple of hours of “working time” the sealant has. Not a problem if you don’t make any mistakes. I made two mistakes. D’oh. There’s a special layering you must follow, the shear plates need to be on top of the stiffeners. On one set, this was not the case and I riveted. Working against the clock now, I get to experience my first attempt and drilling out a pull rivet. Every bit as hard as what I’ve read too, but I managed to get it out. Continued on and on another stiffener/shear plate combination, found they were layered incorrectly. I hadn’t riveted them yet, but I had riveted the solo aft rivet near the trailing edge which prevented me from repositioning, so that had to come out too. Second pull rivet drilling out went much faster because I knew how much effort that was going to take, and didn’t hold back this time.

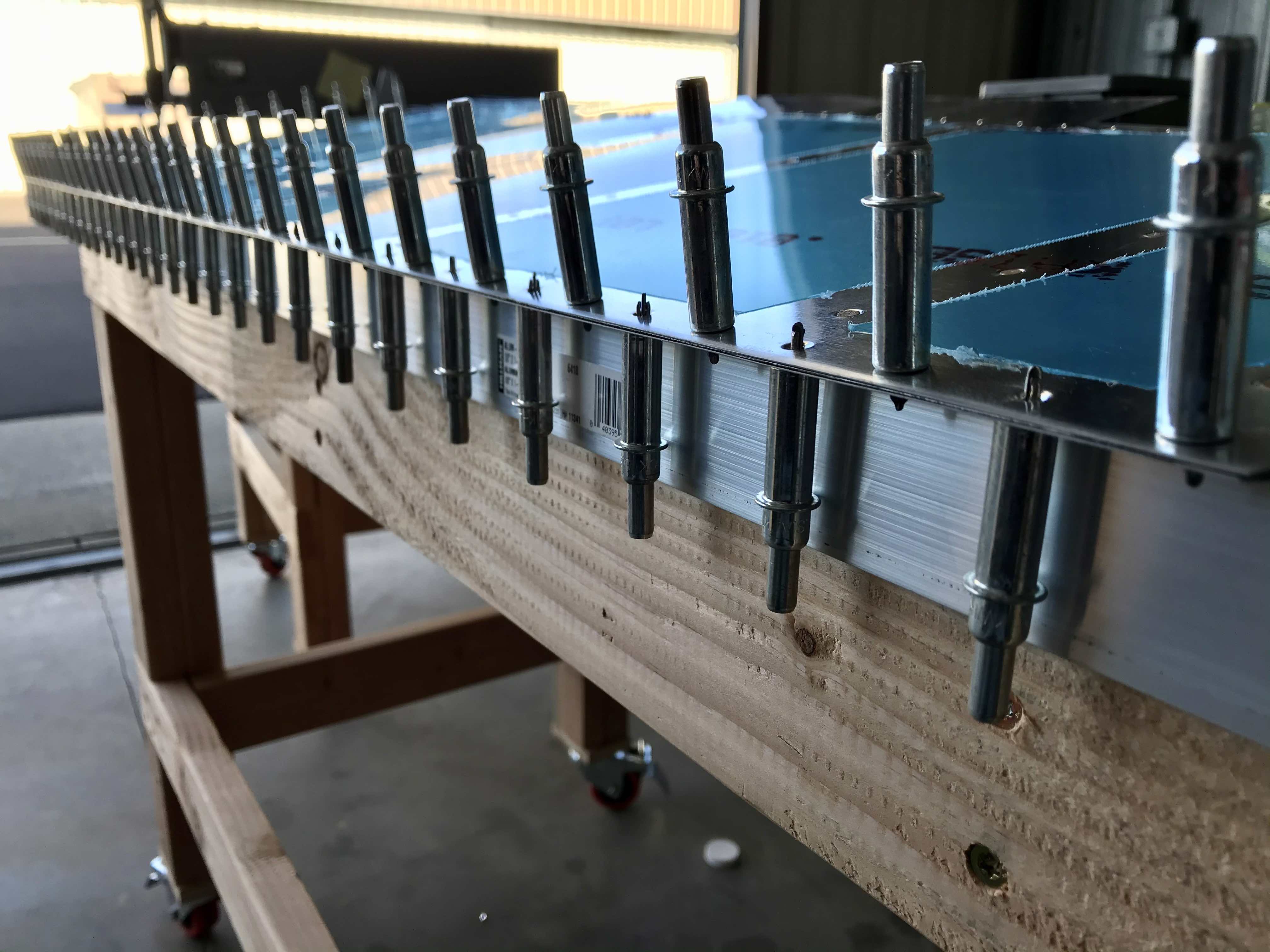

Clecoed the trailing edge in an alternating fashion, and weighted it down against a long piece of angle aluminum. The trailing edge is perfectly straight right now, hope it remains so after I finish the riveting in a day or two.