There is another part I decided to replace… the tie down bar. When I had cut it, the thin bandsaw blade bent when going through the thick part (I need to go much slower), and then through the course of evening the sides, like a bad hair cut, the result was a little too short. This caused the edge distance of the two top holes to be compromised… and at an $8.50 replacement cost (pre-threaded!) it’s no longer going to bother me.

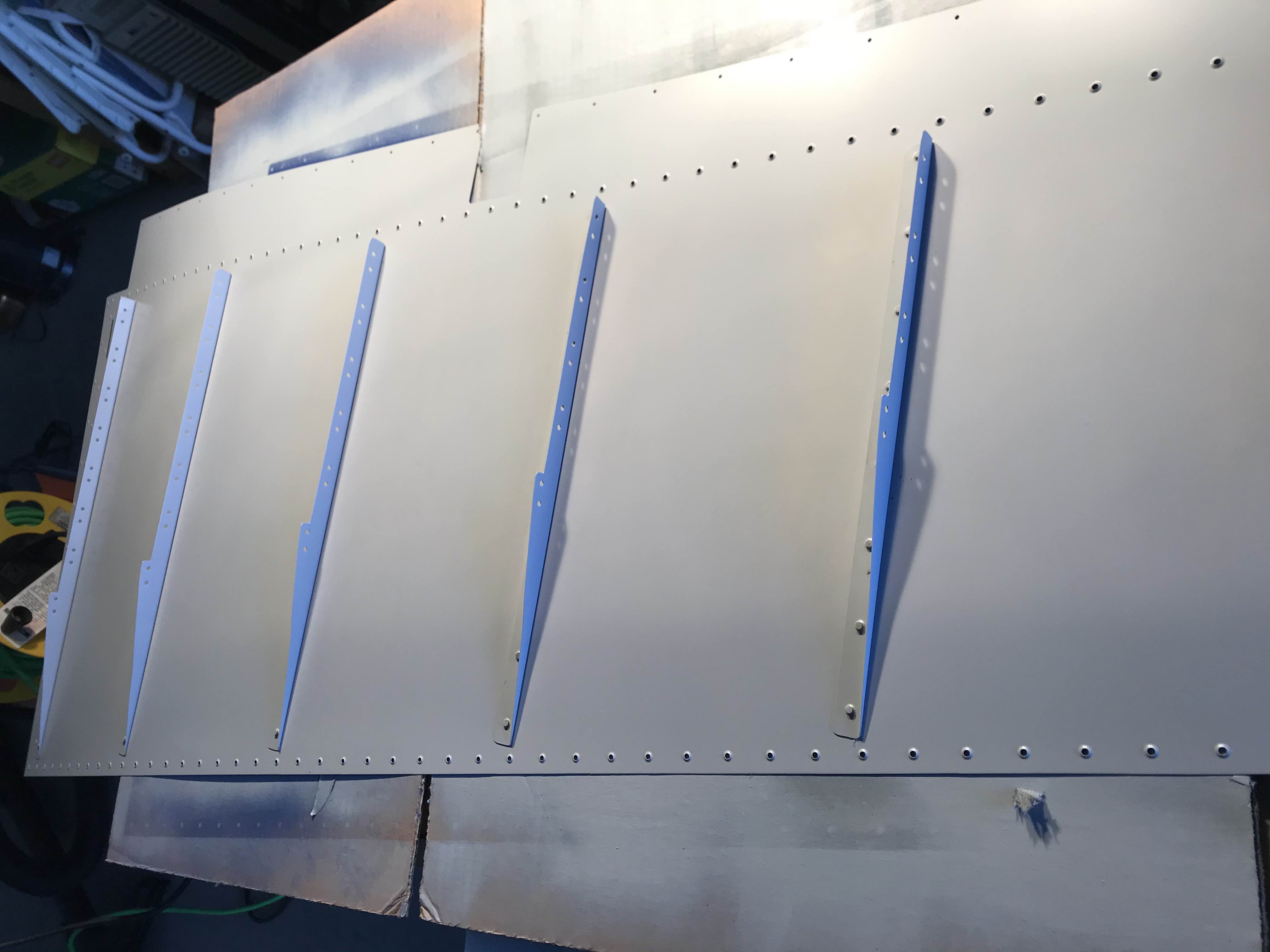

The new left rudder skin certainly does not bother me… I started by dimpling it. It was primed in the last session, and had no issues with dimpling after priming. I also re-made 3 stiffeners. Got those primed, and riveted all the stiffeners on the left rudder skin. Because I did not prime the right skin, I decided that I wanted to now, so I lightly scuffed it, cleaned, and sprayed. It was very lightly scuffed with a gray scotch-brite, the strong halogen lighting just makes it look more aggressive.

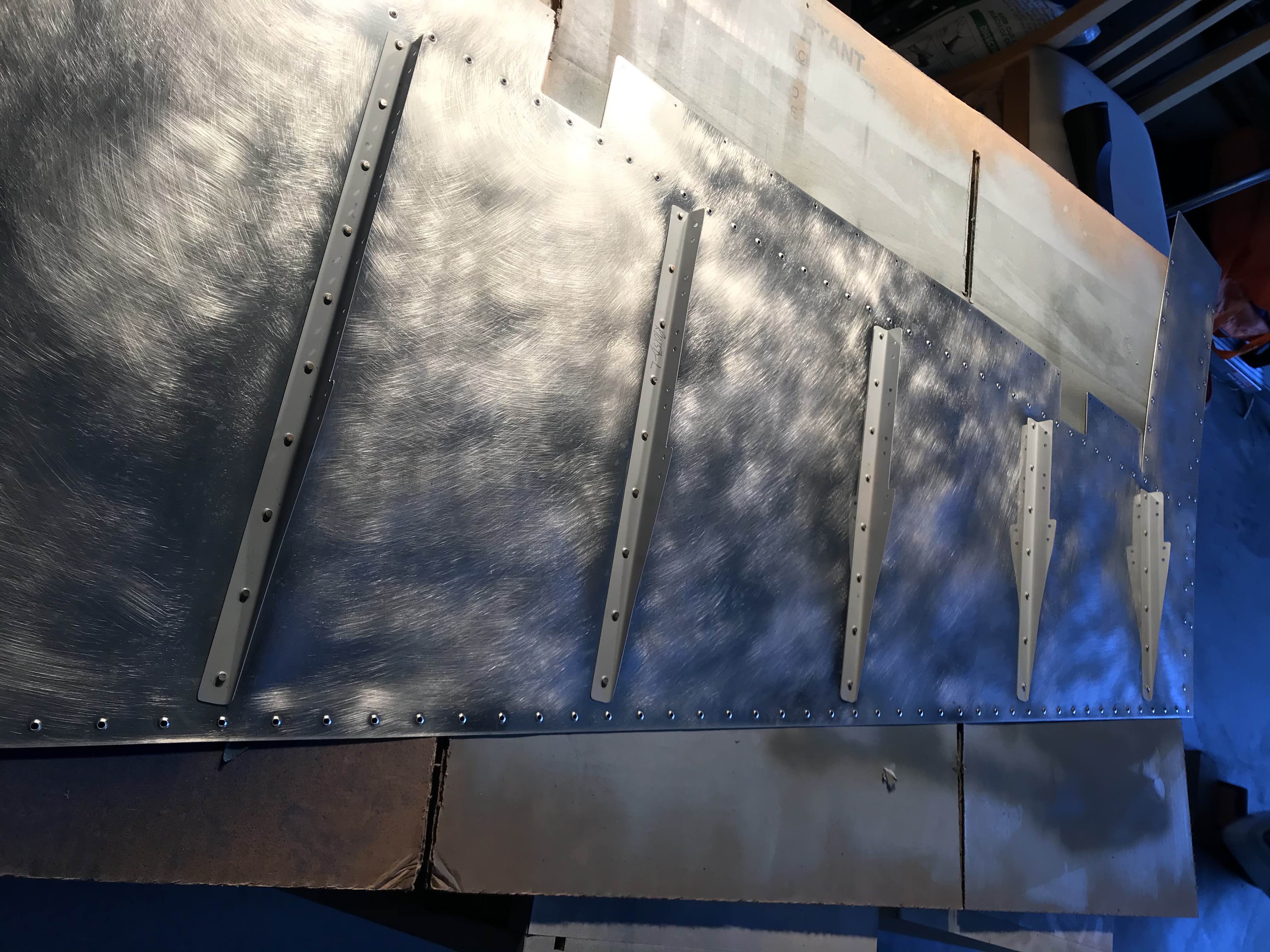

I got well beyond my original left rudder skin by riveting all the stiffeners, plus the rudder horn (with a newly installed nut plate), and top rib riveted on. Two rivets on the rudder horn were inaccessible, I have to locate my crow-bar and use a low-tech hammer, crow-bar, and steel plate riveting approach for those.

Was able to pull out the second hand pneumatic pull rivet tool I acquired, and get the R-1010 shear clips installed to the left skin stiffeners.